Harwell Multi Storey Car Park (MSCP) - Expanded and Perforated Metal Panels

Harwell MSCP Project

Harwell_MSCP_hub2_800x600

Harwell_MSCP_hub_800x600

Harwell_MSCP_hub3_800x600

Harwell_MSCP_external2_800x600

Harwell_MSCP_internal_800x600

Harwell_MSCP_external_800x600

Harwell_MSCP_front_800x600

Harwell_MSCP_internal2_800x600

Harwell_MSCP_perf&exp_800x600

Harwell_ multi_storey_car_parked metal mesh

Harwell_MSCP_perf_800x600

Harwell_MSCP_perf2_800x600

Harwell multi storey car park expanded metal mesh

Harwell multi storey car park expanded metal mesh

Harwell multi storey car park expanded corten mesh and green perforated metal

Harwell multi storey car park expanded corten mesh

Harwell_mscp_corten_mesh_800x600

Harwell_mscp_entrance_800x600

Harwell_mscp_full_quote_800x600

Harwell_mscp_full_rear_800x600

Harwell_mscp_image_perf_800x600

Harwell_mscp_solid_panels_800x600

Harwell_mscp_full_800x600

Harwell_mscp_corten_mesh_2_800x600

Harwell_mscp_corten_mesh2_800x600

About the Project

This multi storey car park in Harwell uses two different types of metal mesh panels:

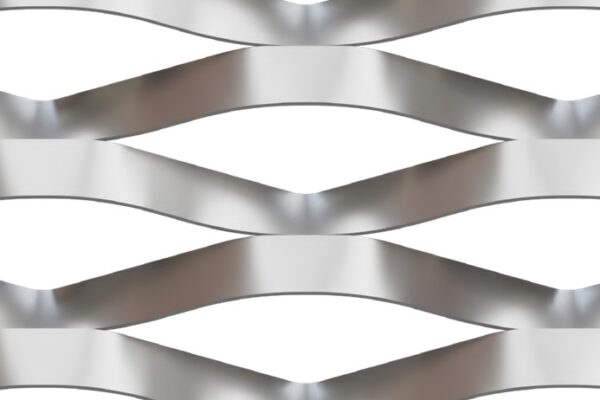

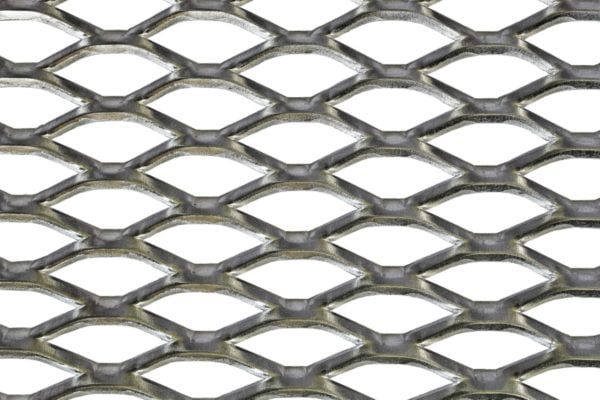

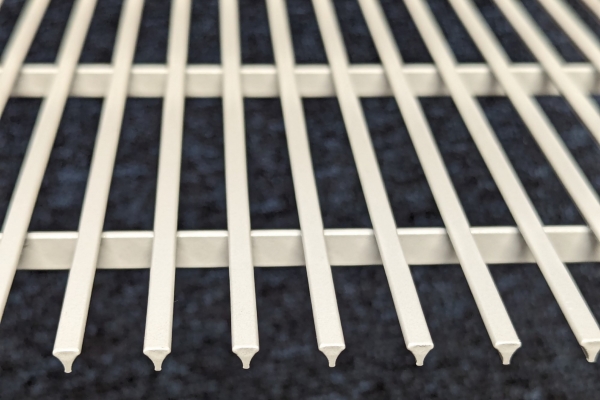

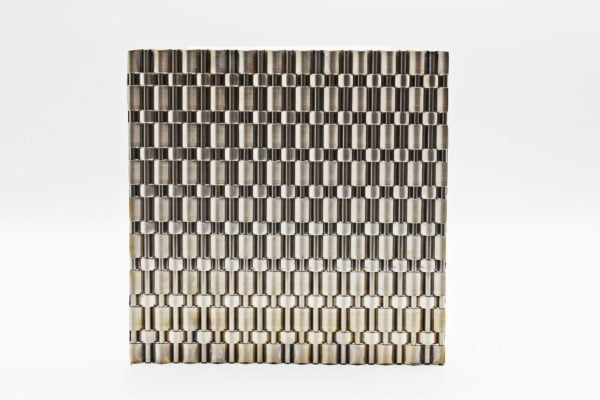

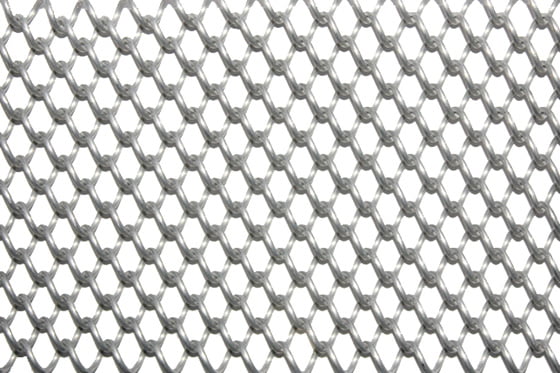

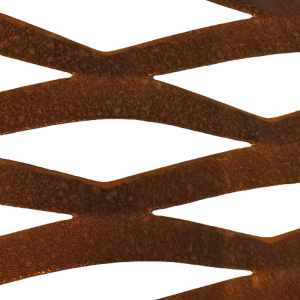

- The Manhattan XL pattern expanded metal panels used for the main facades, enclose the parking areas on all floors above ground level. These are manufactured from Corten Steel, also known as weathering steel, which was designed to eliminate the need for painting and when exposed to the elements, develops a rusted appearance. The images above show how the mesh has weathered during the construction period.

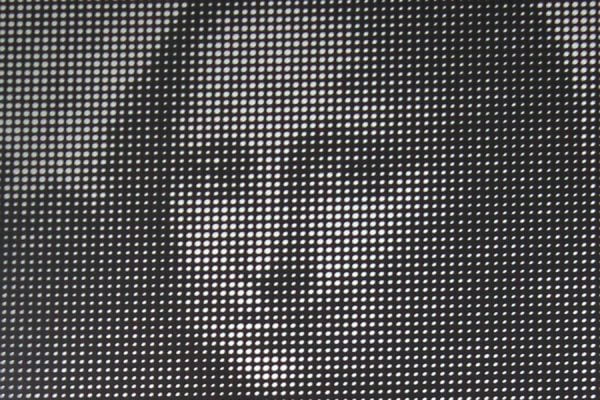

- RMIG ImagePerf perforated and anodised aluminium sheet is used for the ground floor facades. Some panels are embossed with the name of the facility.

There are also decorative V-shaped panels made from both materials.

The perforated metal mesh was preferred for the ground floor as it provides additional security whilst still allowing ventilation and natural light penetration.

This sample of expanded metal mesh in Corten steel shows the finish patina after 3 weeks of exposure to the British weather.