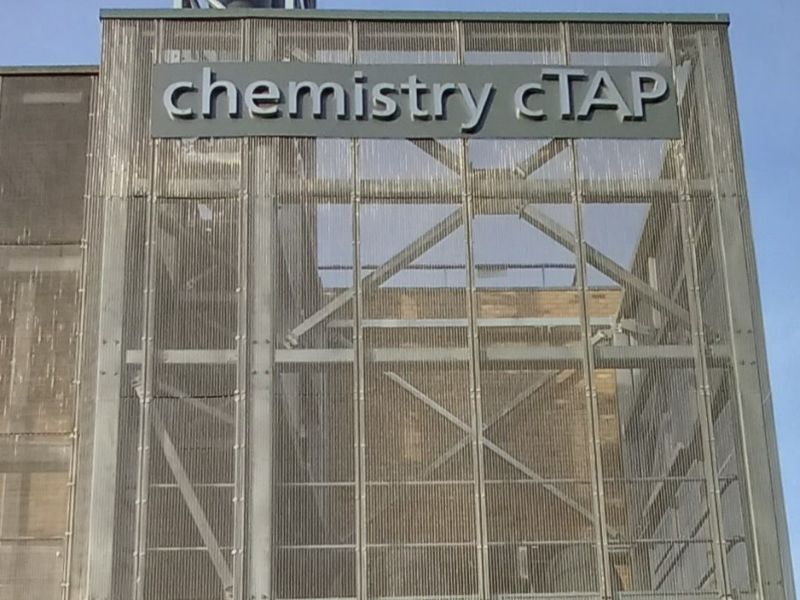

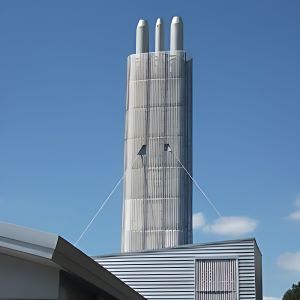

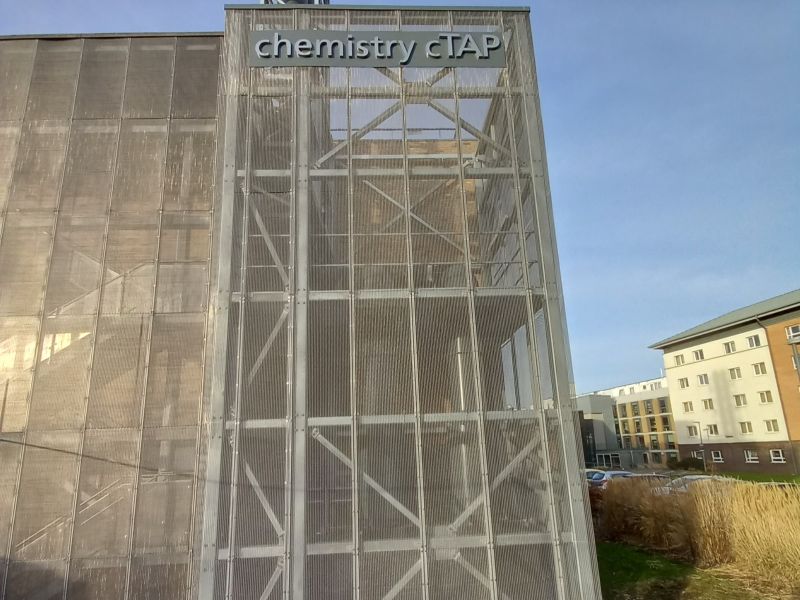

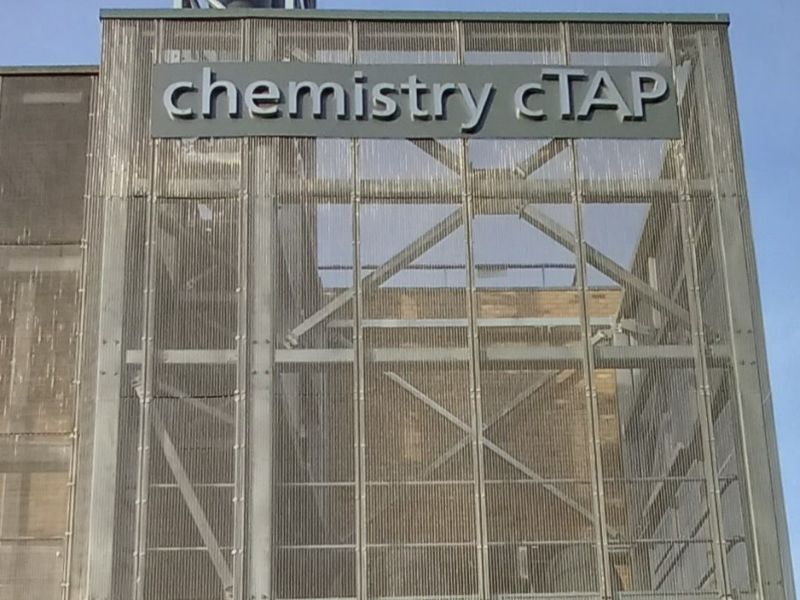

Flue and Plant Screening Mesh Cladding at Lancaster University

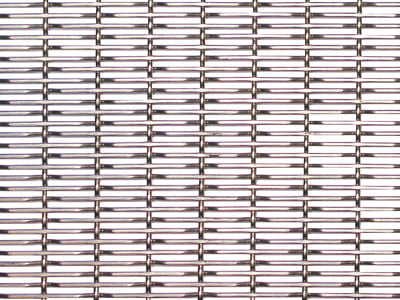

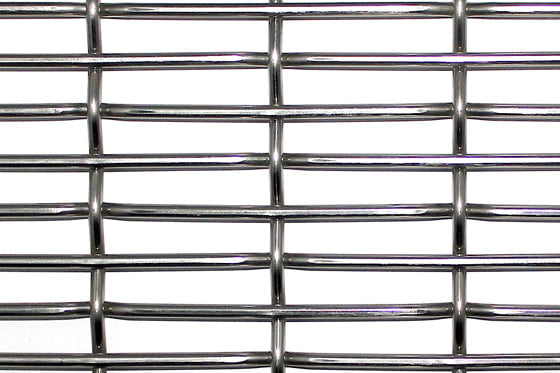

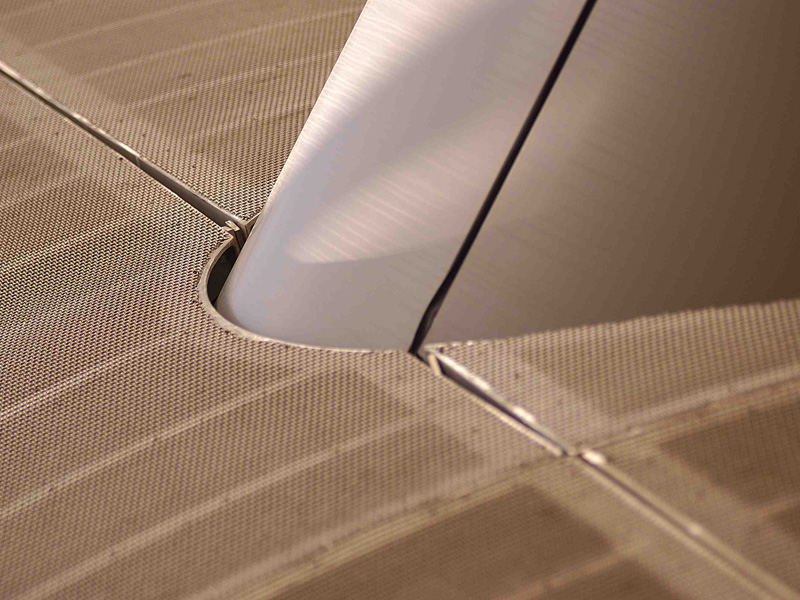

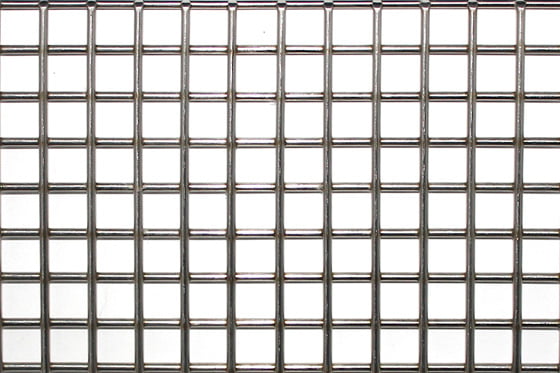

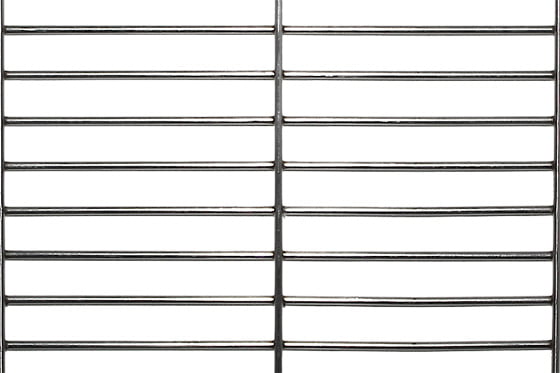

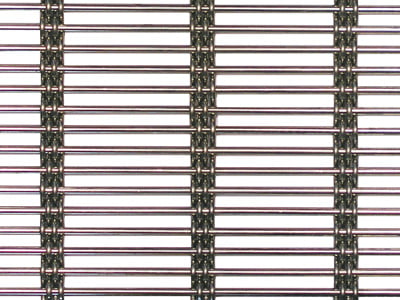

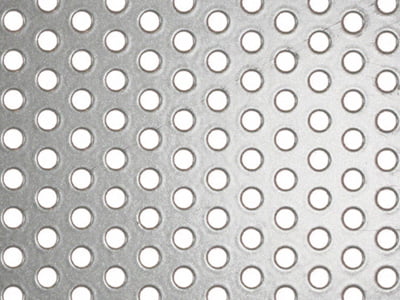

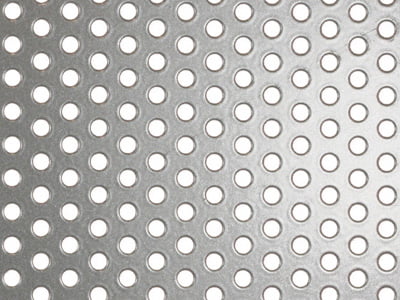

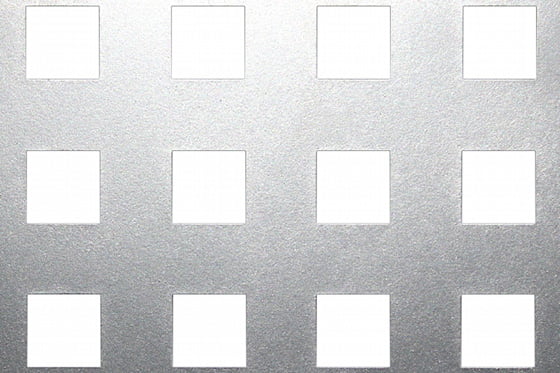

pre-crimped-mesh-flue-screening-panels-closeup

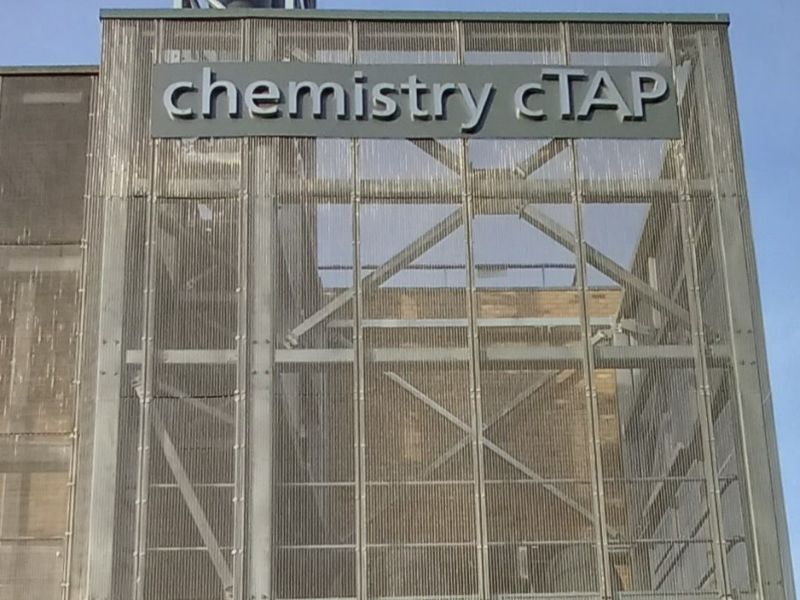

pre-crimped-mesh-flue-screening-panels-closeup3

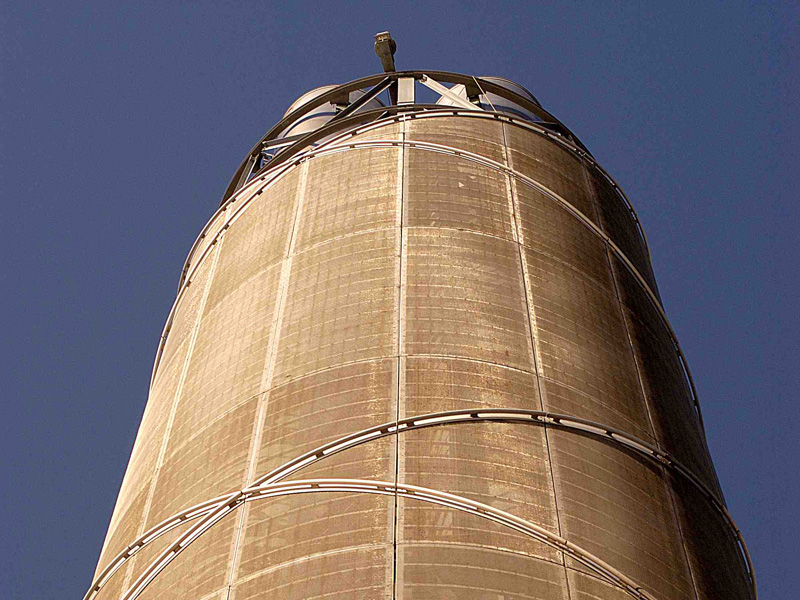

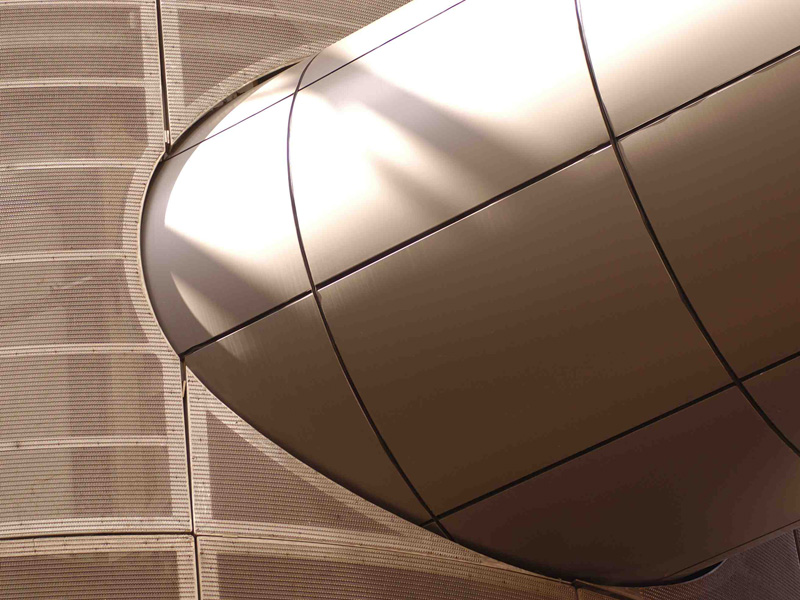

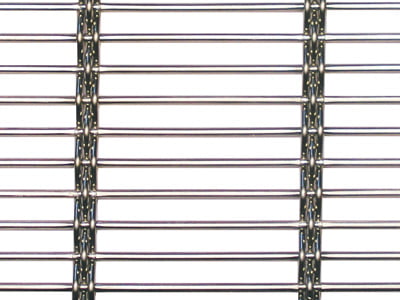

pre-crimped-mesh-flue-screening-panels

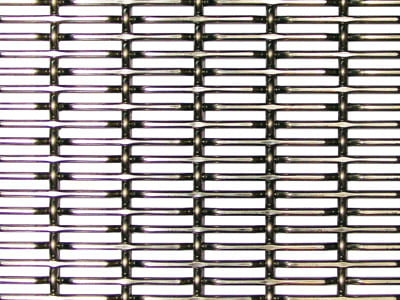

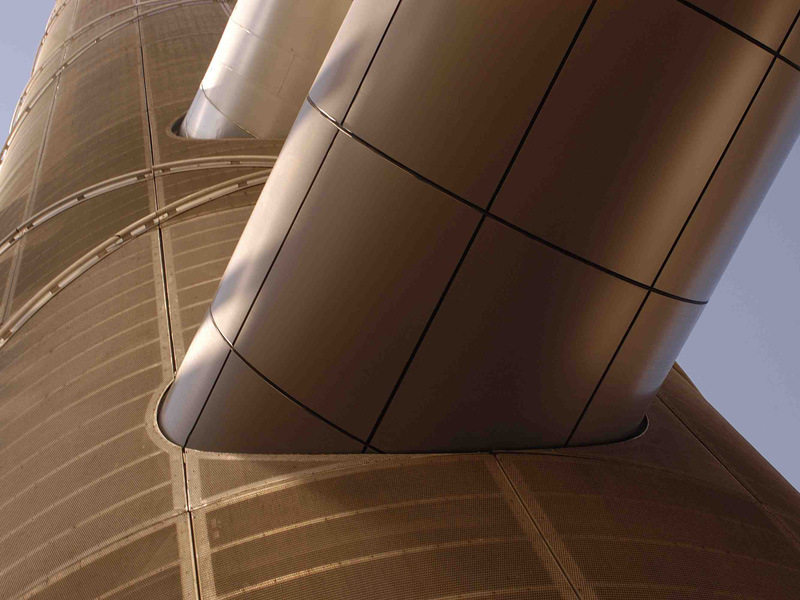

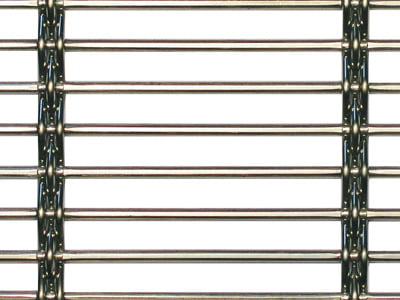

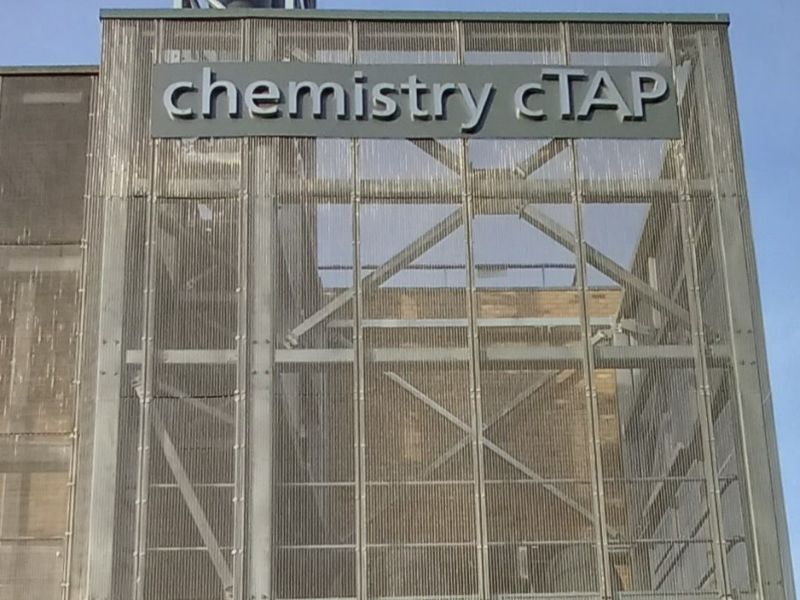

pre-crimped-mesh-flue-screening-panels-closeup2

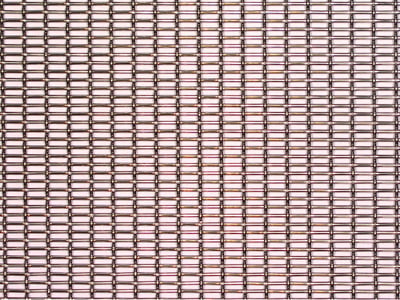

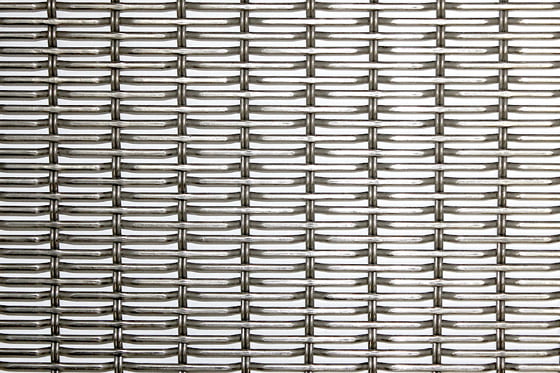

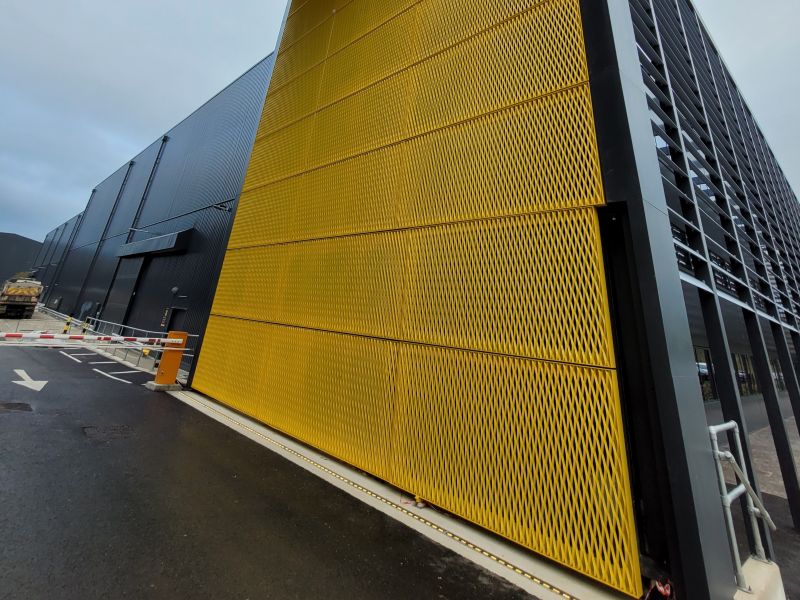

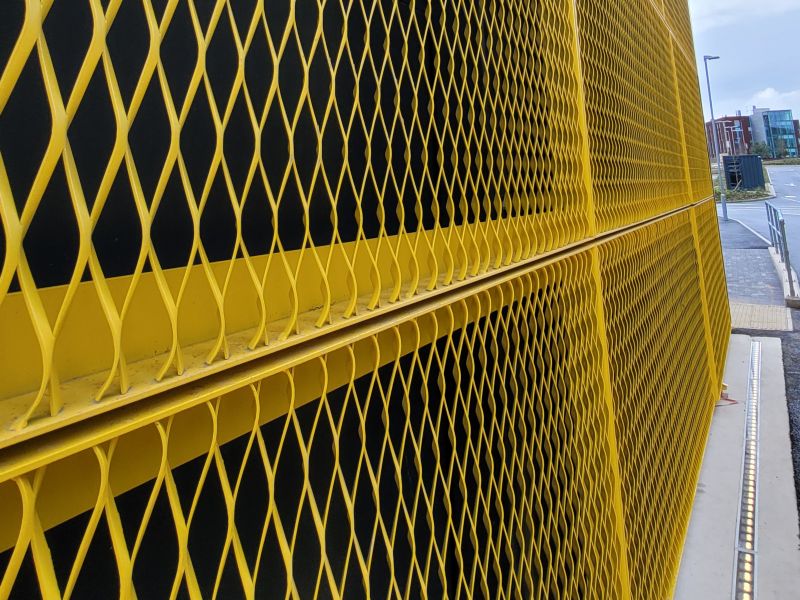

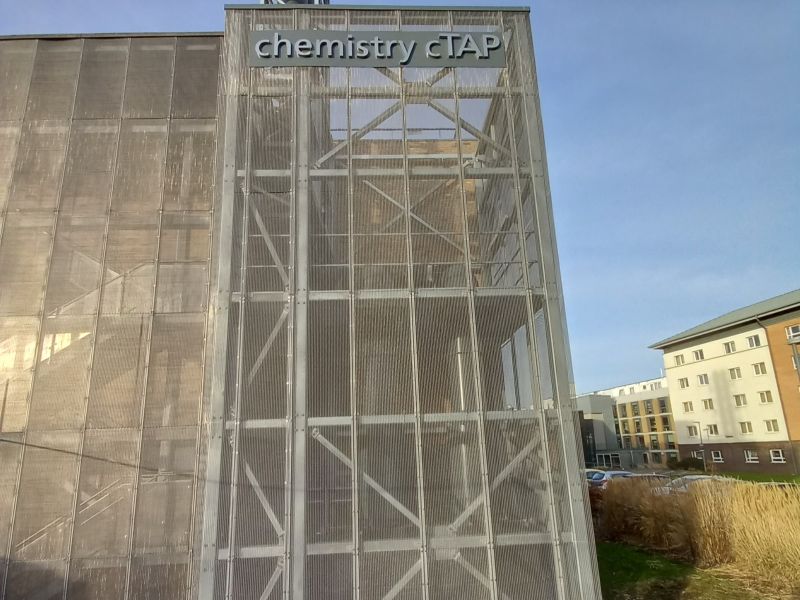

pre-crimped-mesh-plant-screening-panels-closeup2

pre-crimped-mesh-plant-screening-panels-closeup

pre-crimped-mesh-flue-screening-panels-closeup4

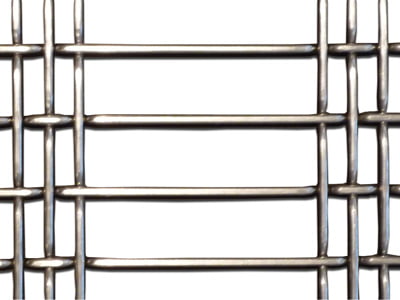

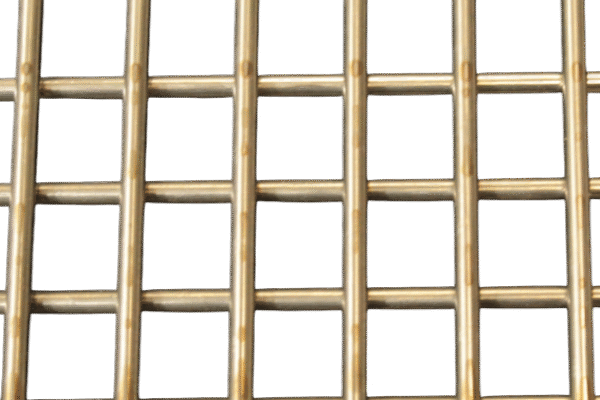

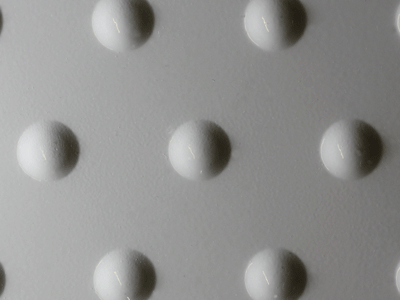

pre-crimped-mesh-facade-panel-closeup

About the Project

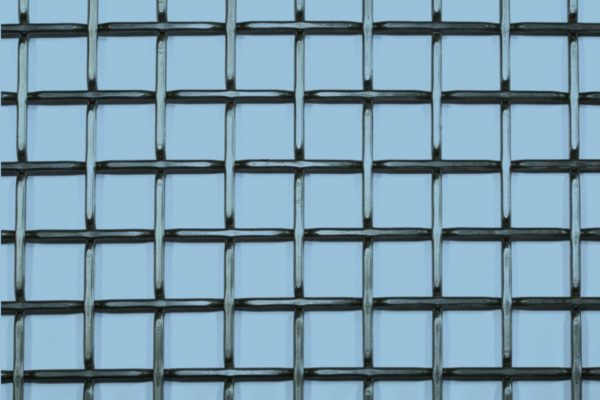

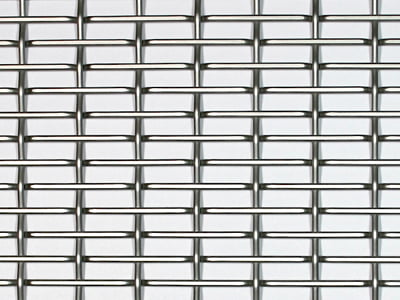

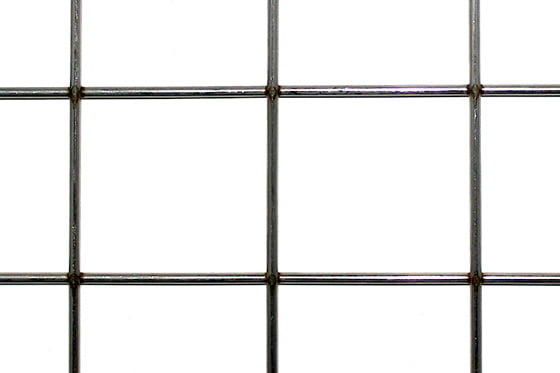

Brocklebank pre-crimped mesh panels were an ideal choice for Plant and Flue Screening at Lancaster University's cTAP facility. The open area of the mesh allows for efficient ventilation, whilst still providing a visual screen and also preventing unauthorised access. The project sustainability is enhanced due to the panels being made from recycled material, and with no paint or other coatings required, the panels are 100% recyclable at end of life.