Flash Architectural Wedge Wire Panels

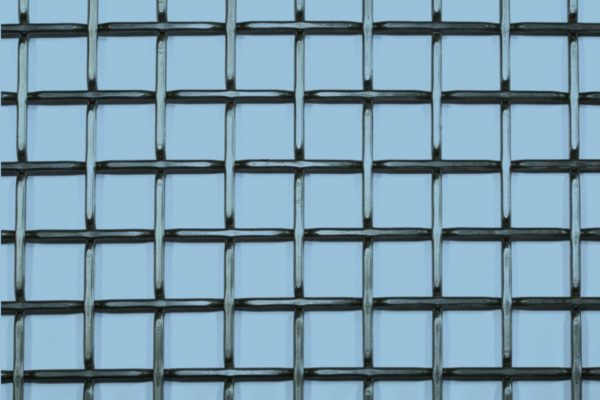

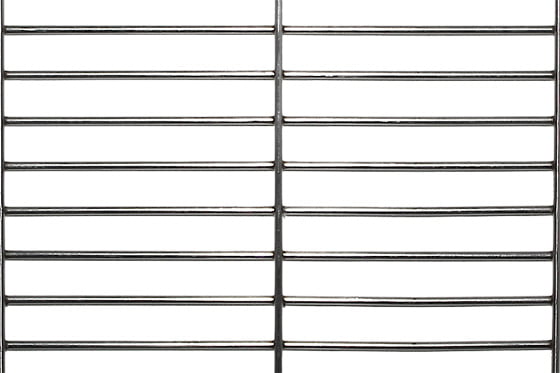

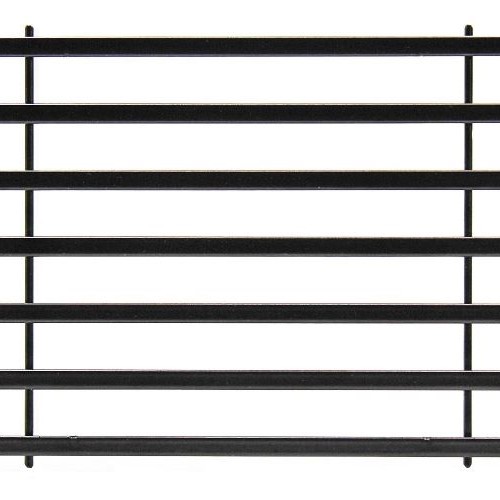

Flash Z02170 C8 15x2 Aluminium with Black finish

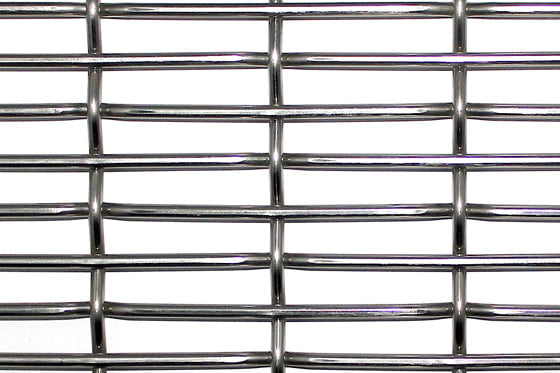

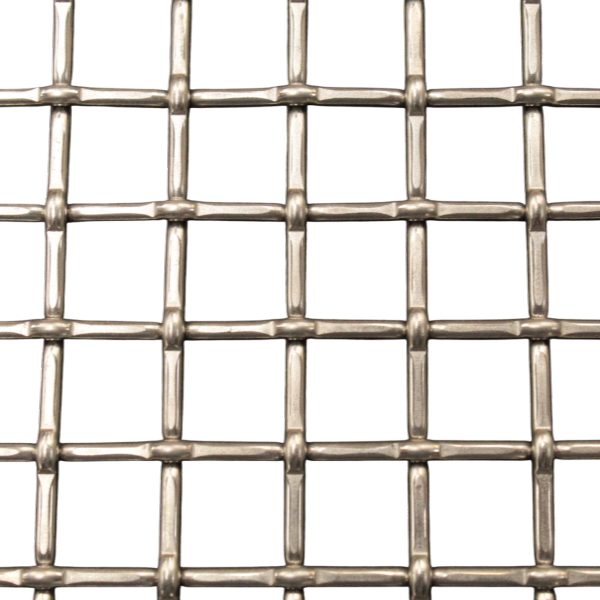

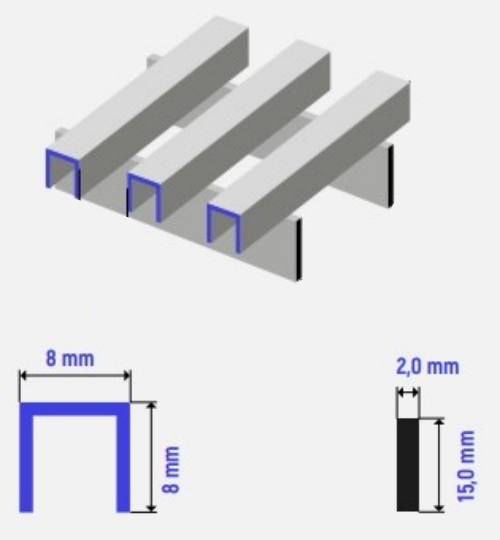

Specification

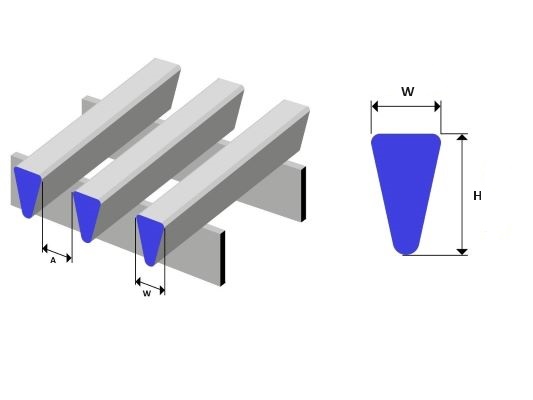

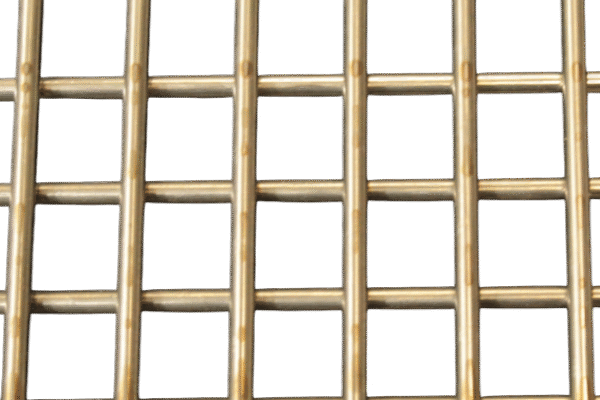

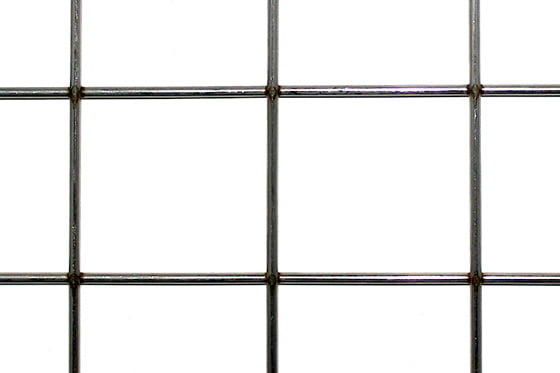

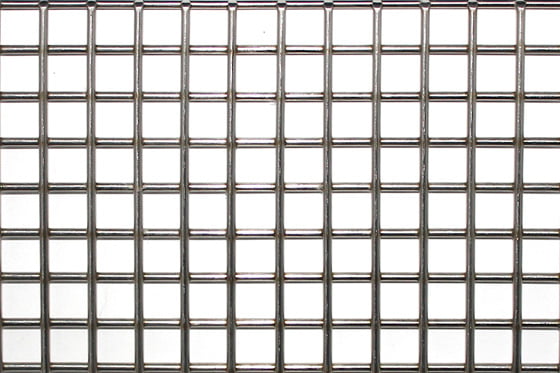

| Wedge Wire Material | Aluminium |

| Wedge Profile (w x h) | 8 x 8 mm |

| Aperture (A) | From 8 mm to 50 mm |

| Support Rods | 15 mm x 2 mm (not suitable for pedestrian use) |

| Framing | As required subject to application |

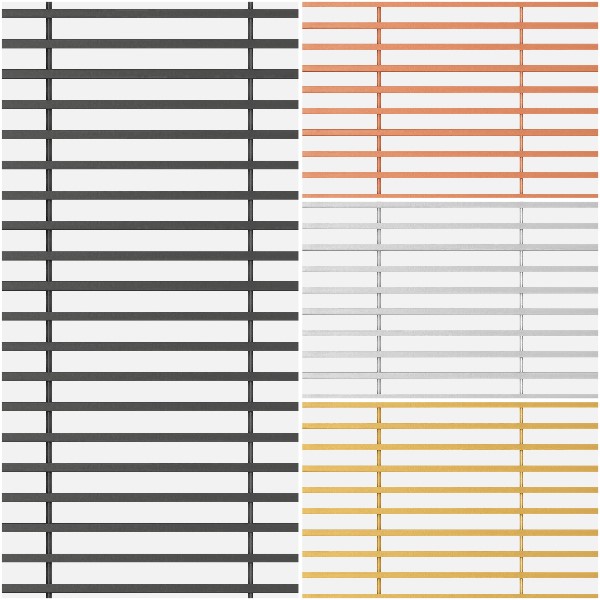

| Finish | Bare metal or Powder coated (specify RAL No. for colour) |

Please note: The above information is a guide to the wide range of options available. Contact our sales team for help in selecting the correct product for your application.

Flash, Aluminium Architectural Wedge Wire pdf specification sheet

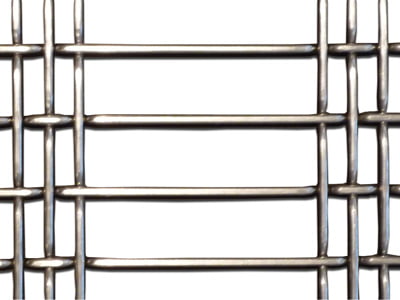

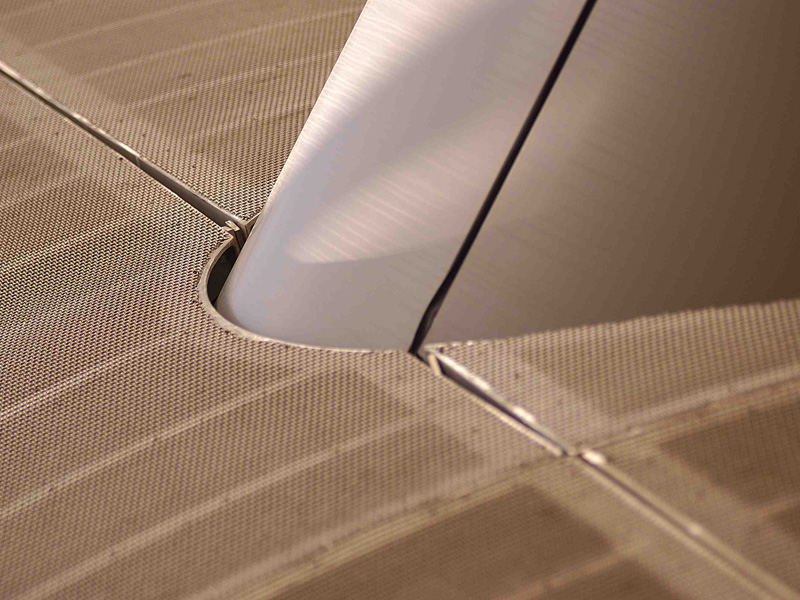

Flash Wedge Wire Panel Construction

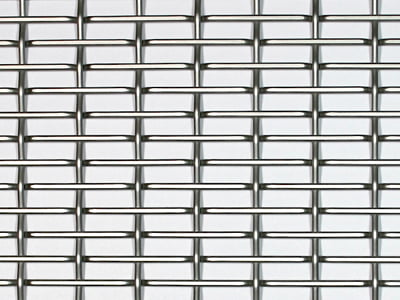

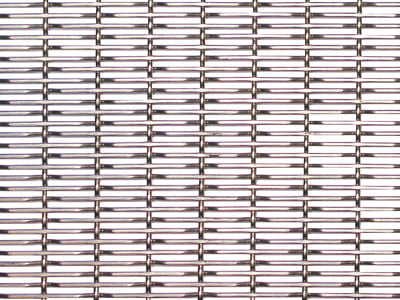

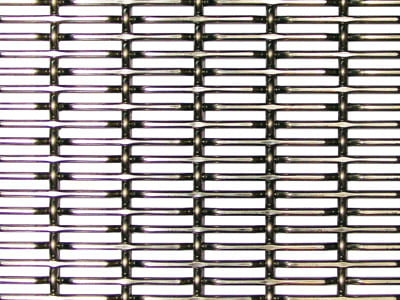

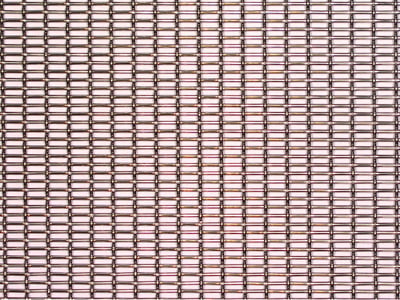

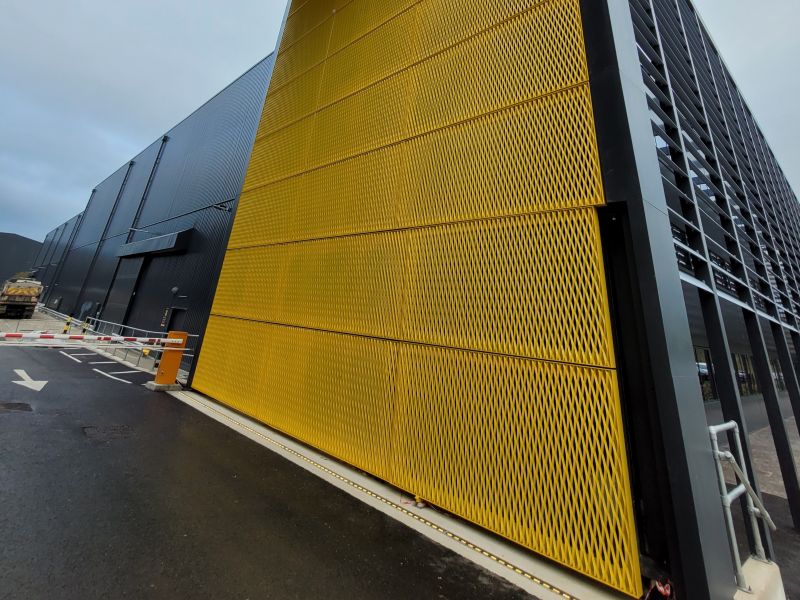

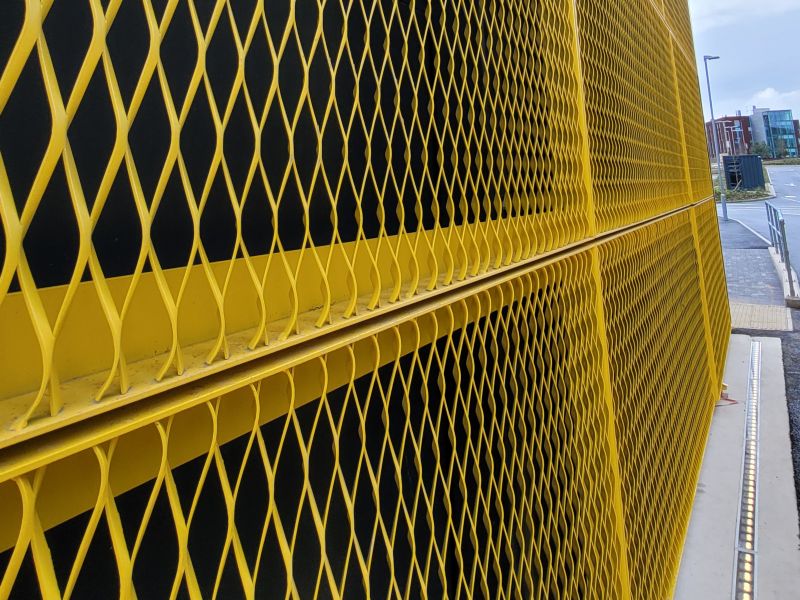

Flash Colour Examples

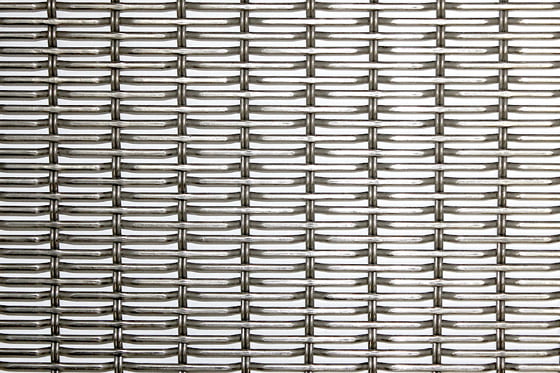

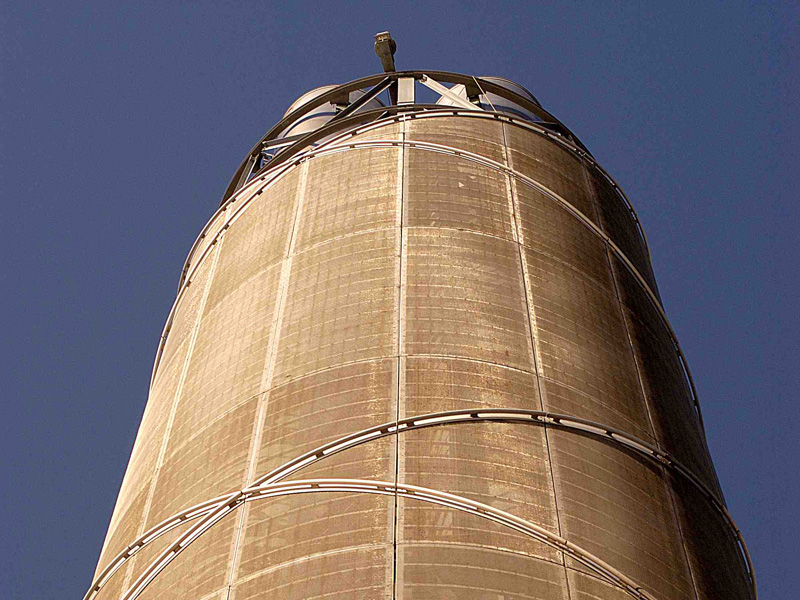

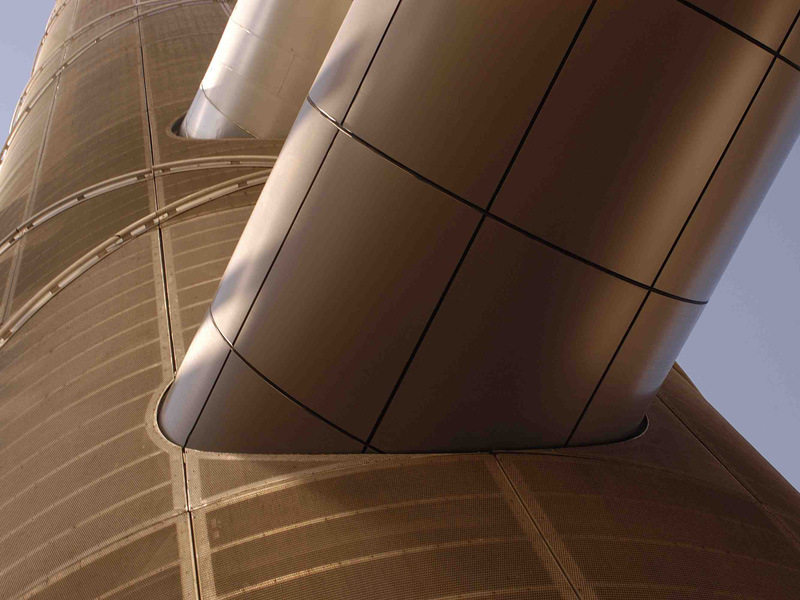

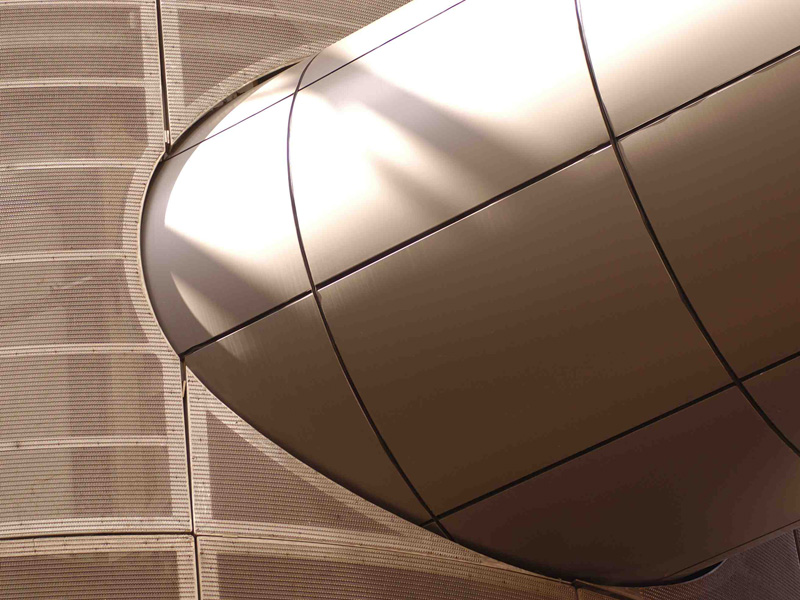

Flash wedge wire is made from Aluminium and features a U-shaped, square profile. This reduces overall weight whilst maintaining structural integrity, making this pattern ideal for ceiling applications.

Flash Colour Examples: Black, Copper, Silver, Gold. Specify the RAL number for your required colour.

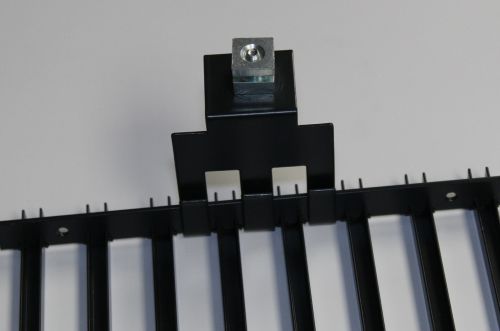

Single and Dual Panel Mounting Clips, for Fast Installation to Supporting Structure

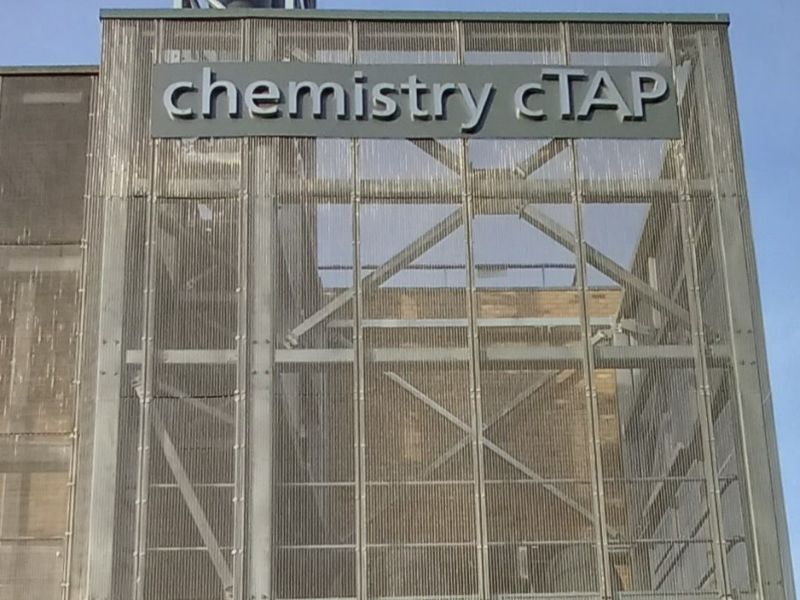

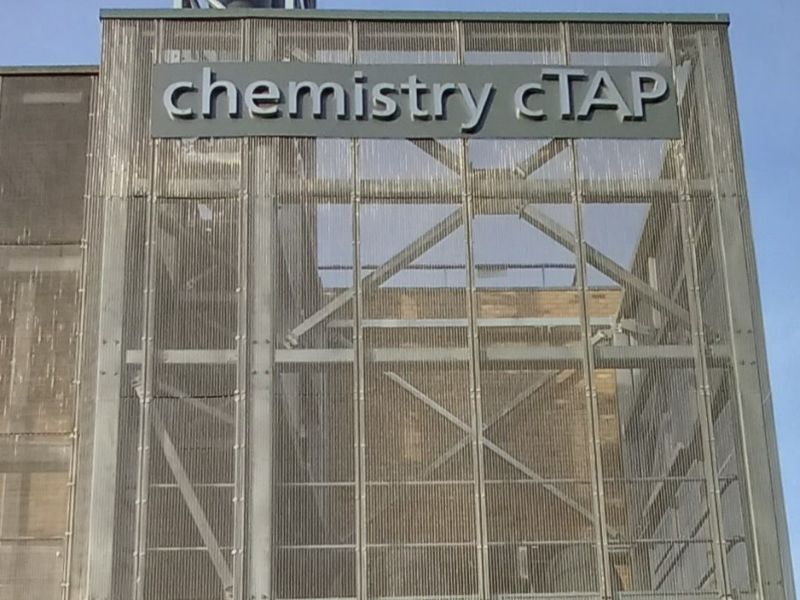

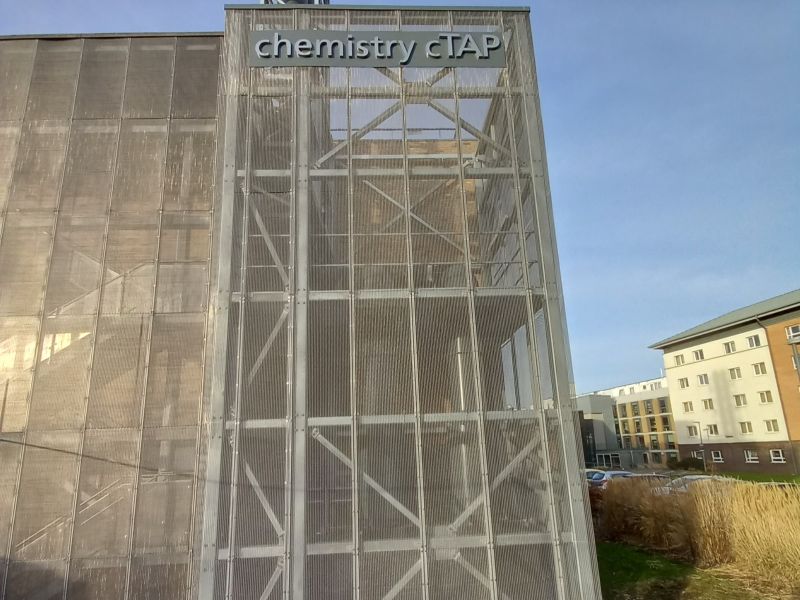

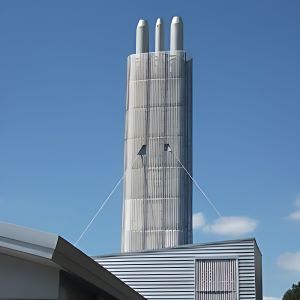

Typical Applications

Ceiling tiles or panels, decorative façades, partitions and screens.

With comprehensive in-house 3D design facilities, we are able to offer a complete package from development of the architectural wire mesh specification through design, fabrication, and delivery to site as and when required for installation.

Flash wedge wire grill is a Progress Architecture product, supplied and distributed in the UK and Ireland by Locker Architectural.