2 Cumberland Place, Dublin

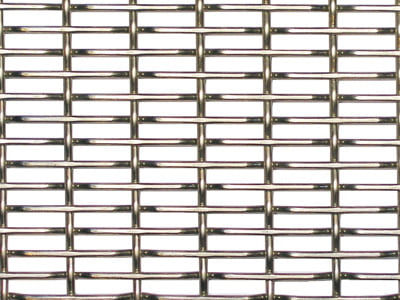

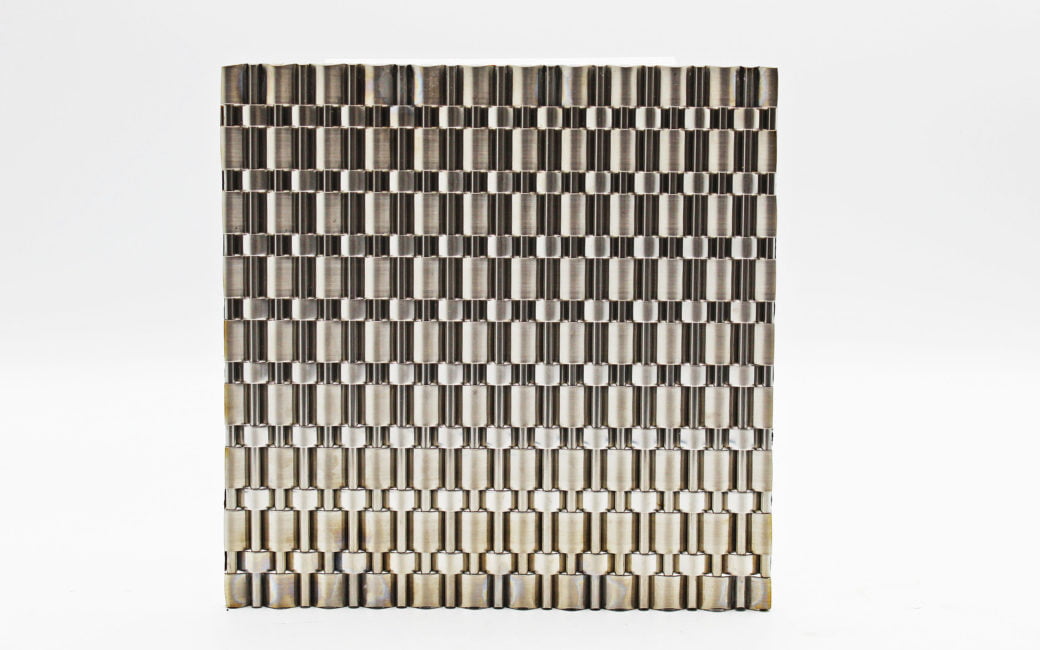

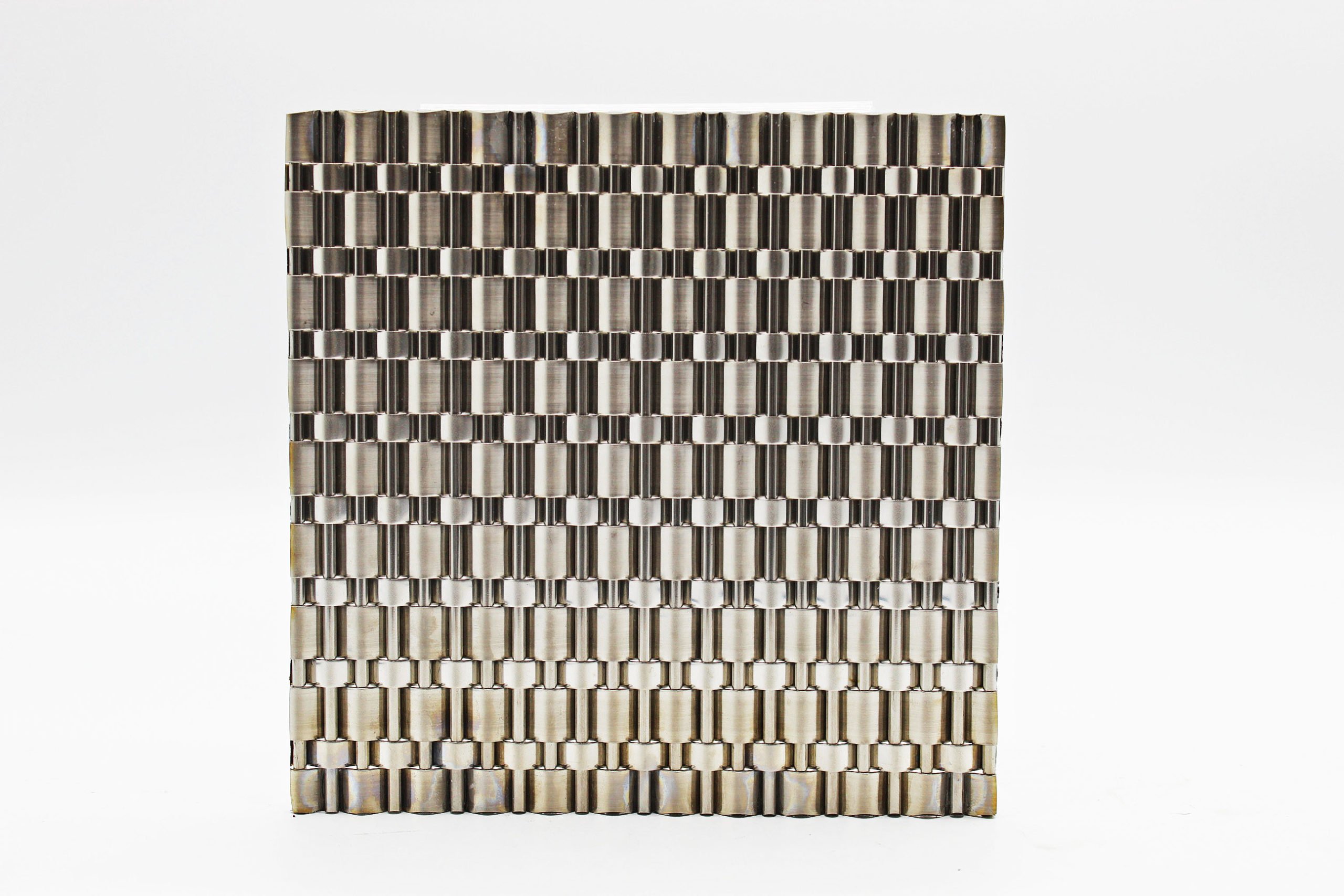

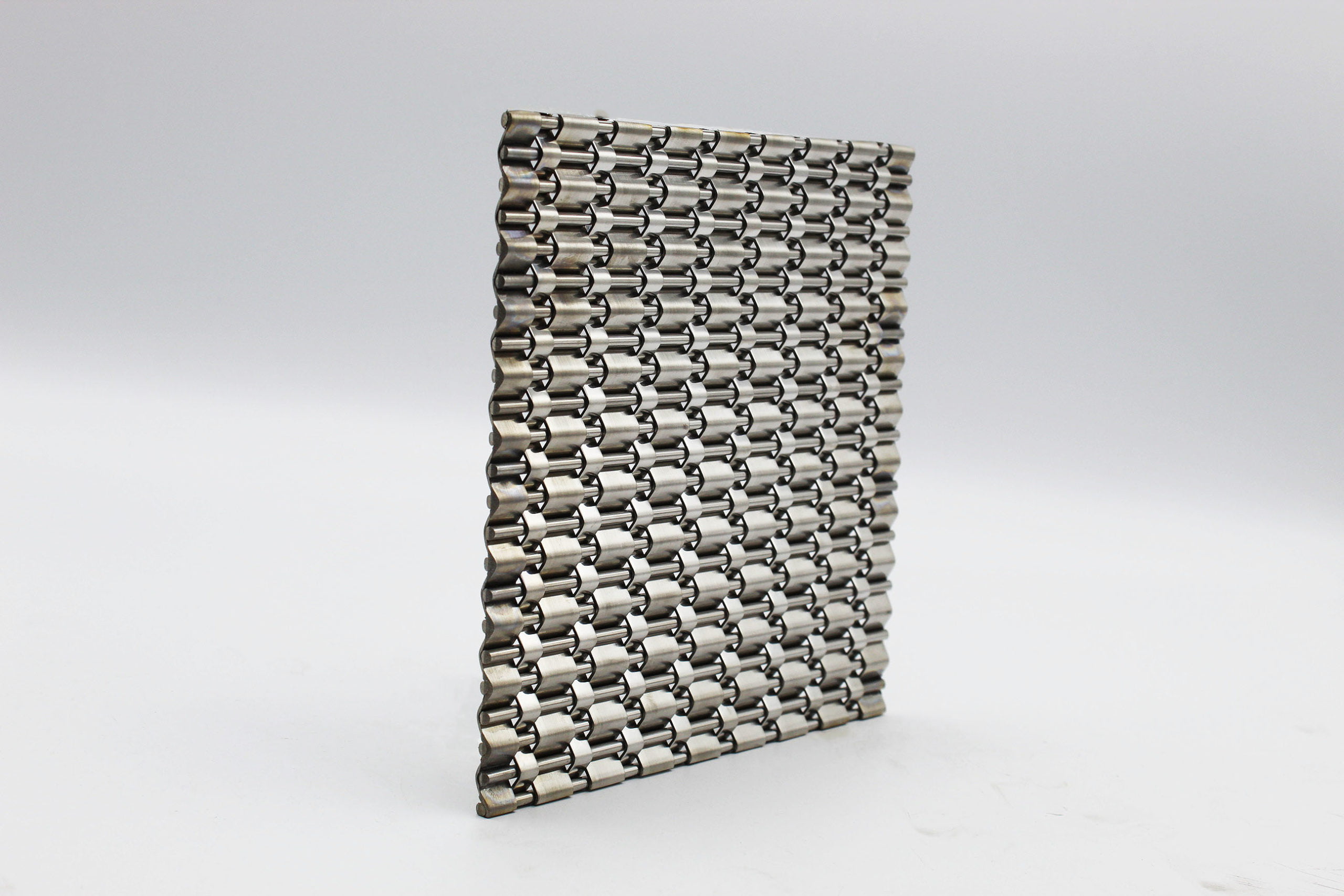

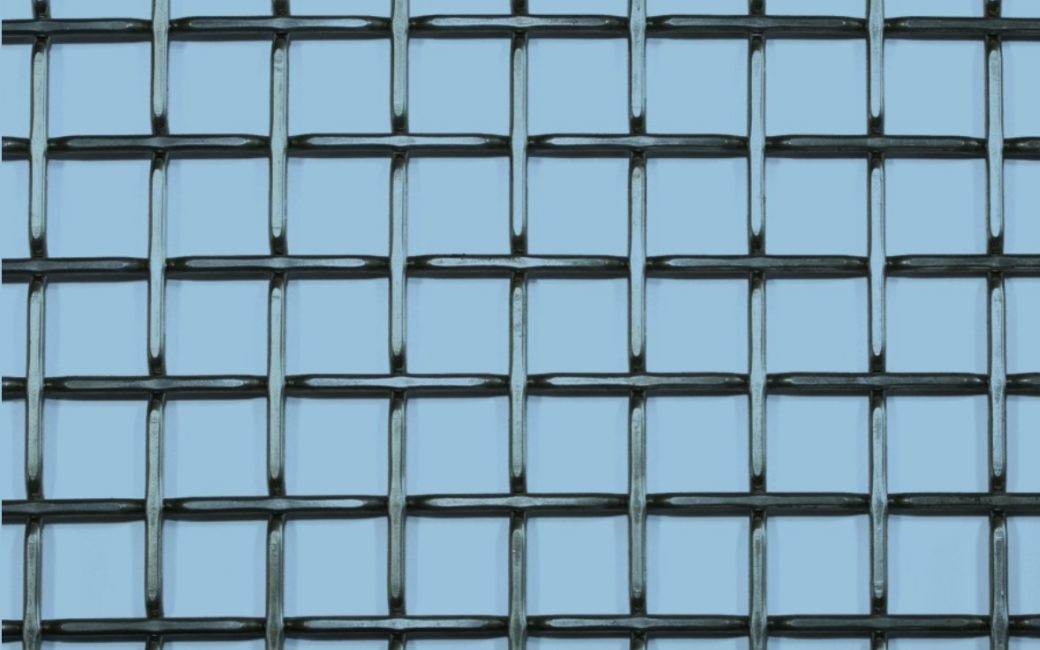

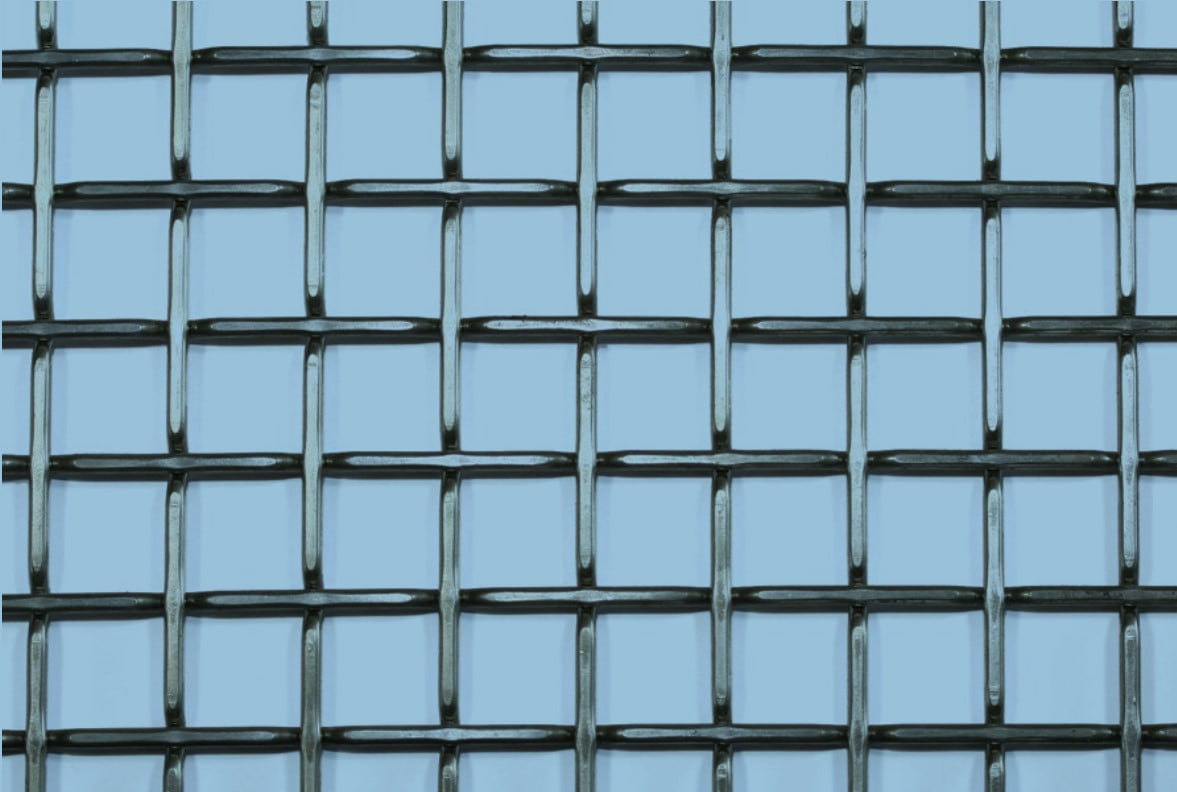

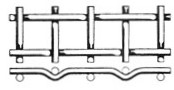

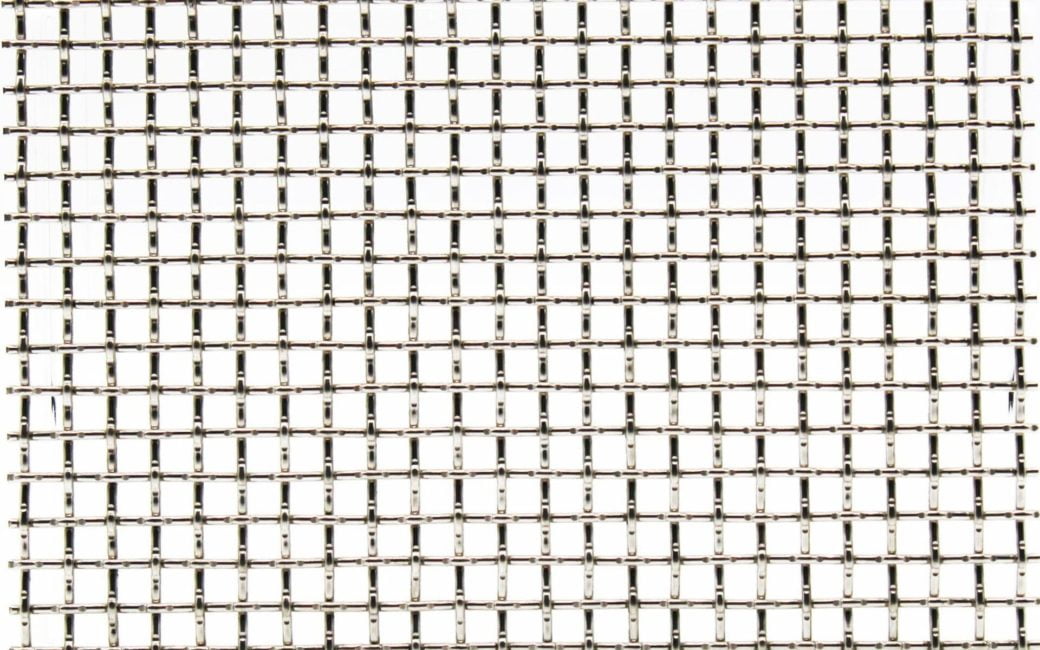

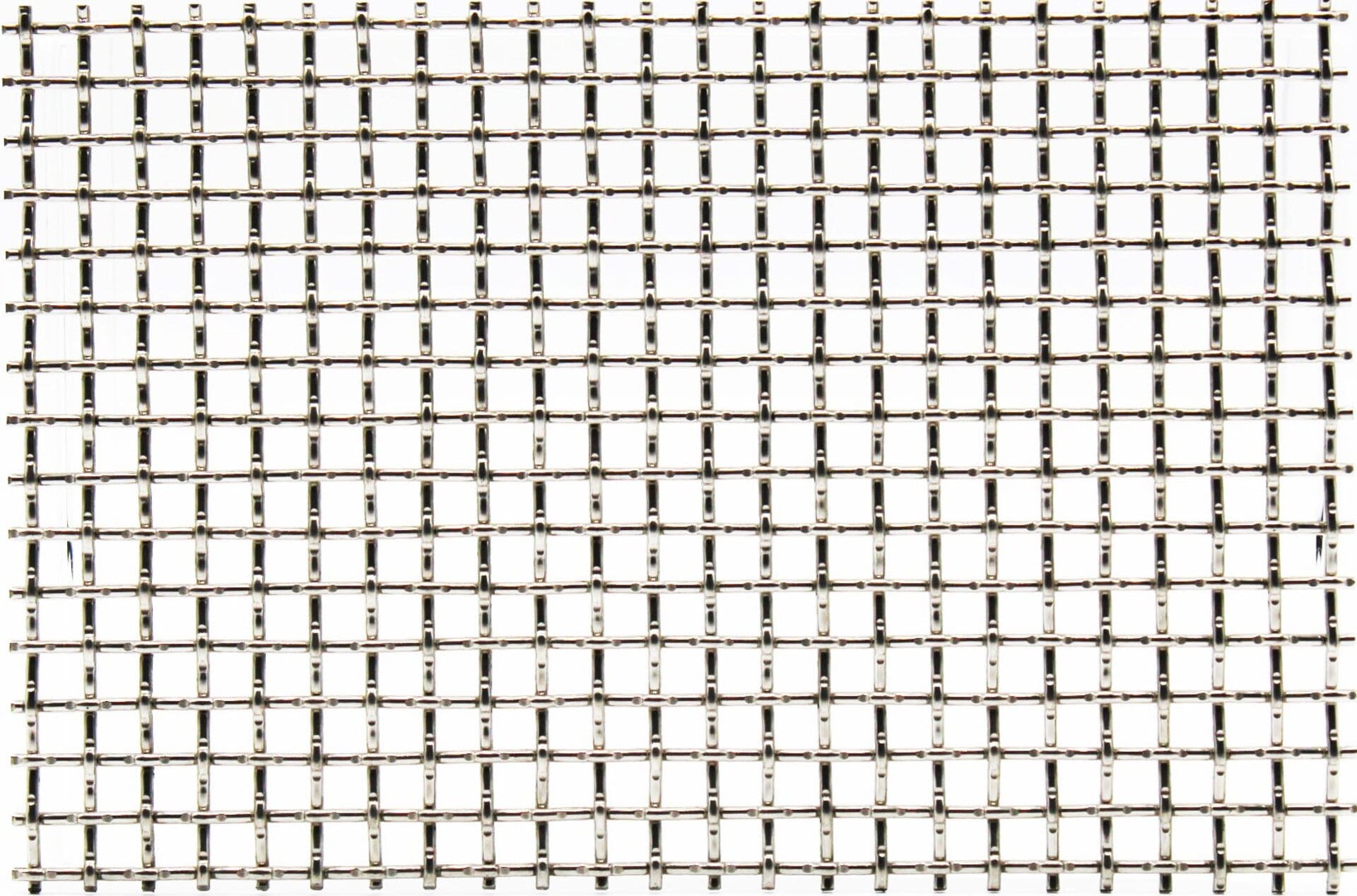

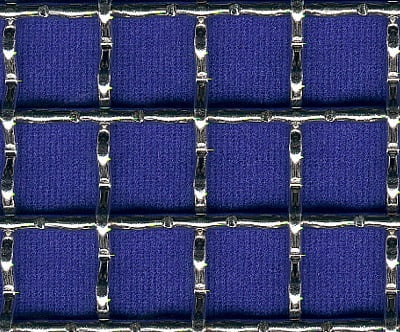

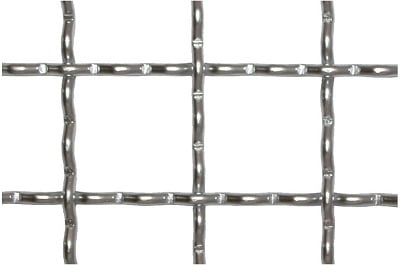

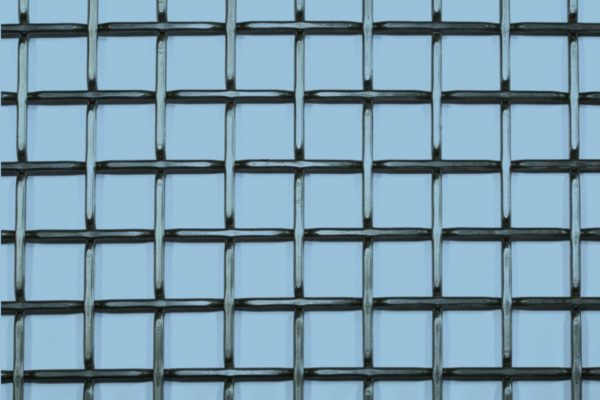

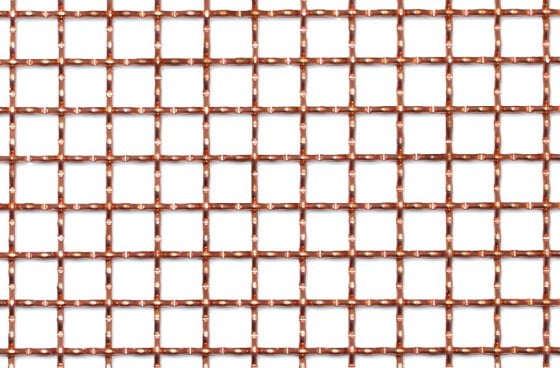

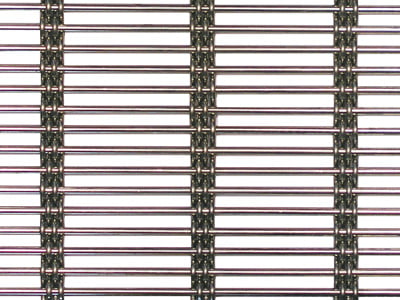

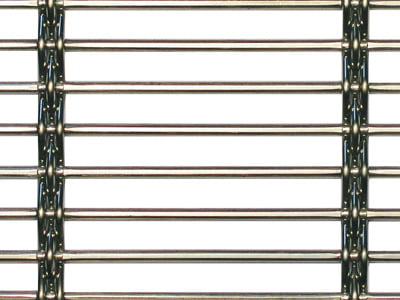

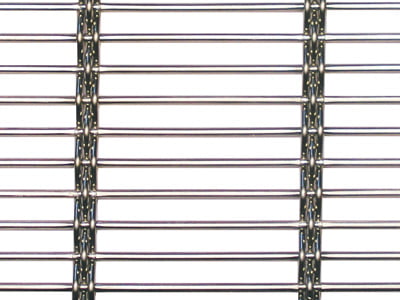

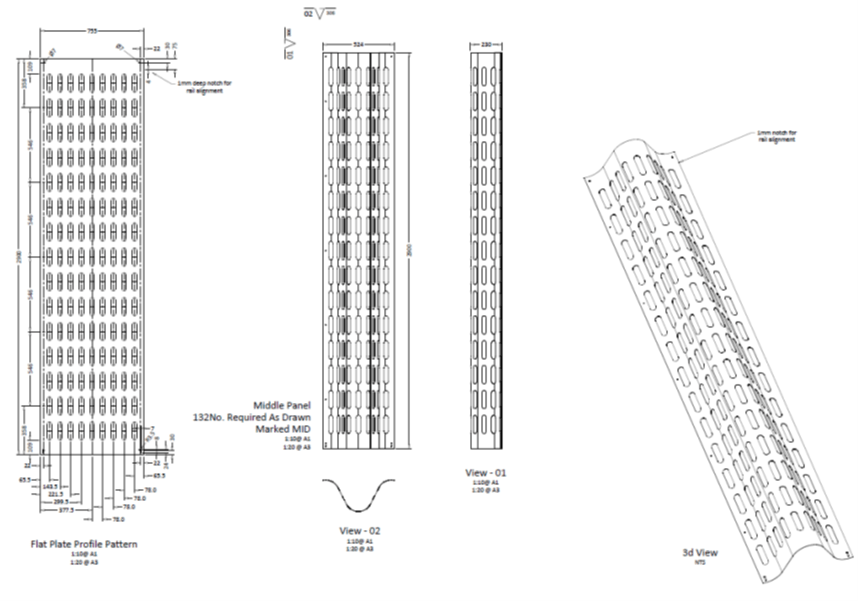

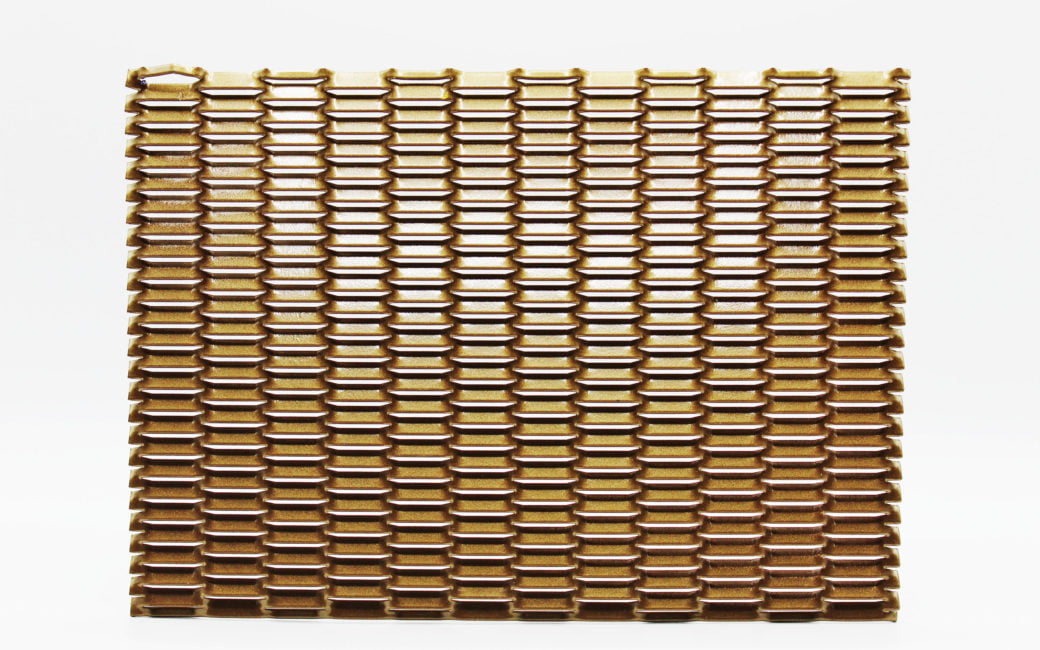

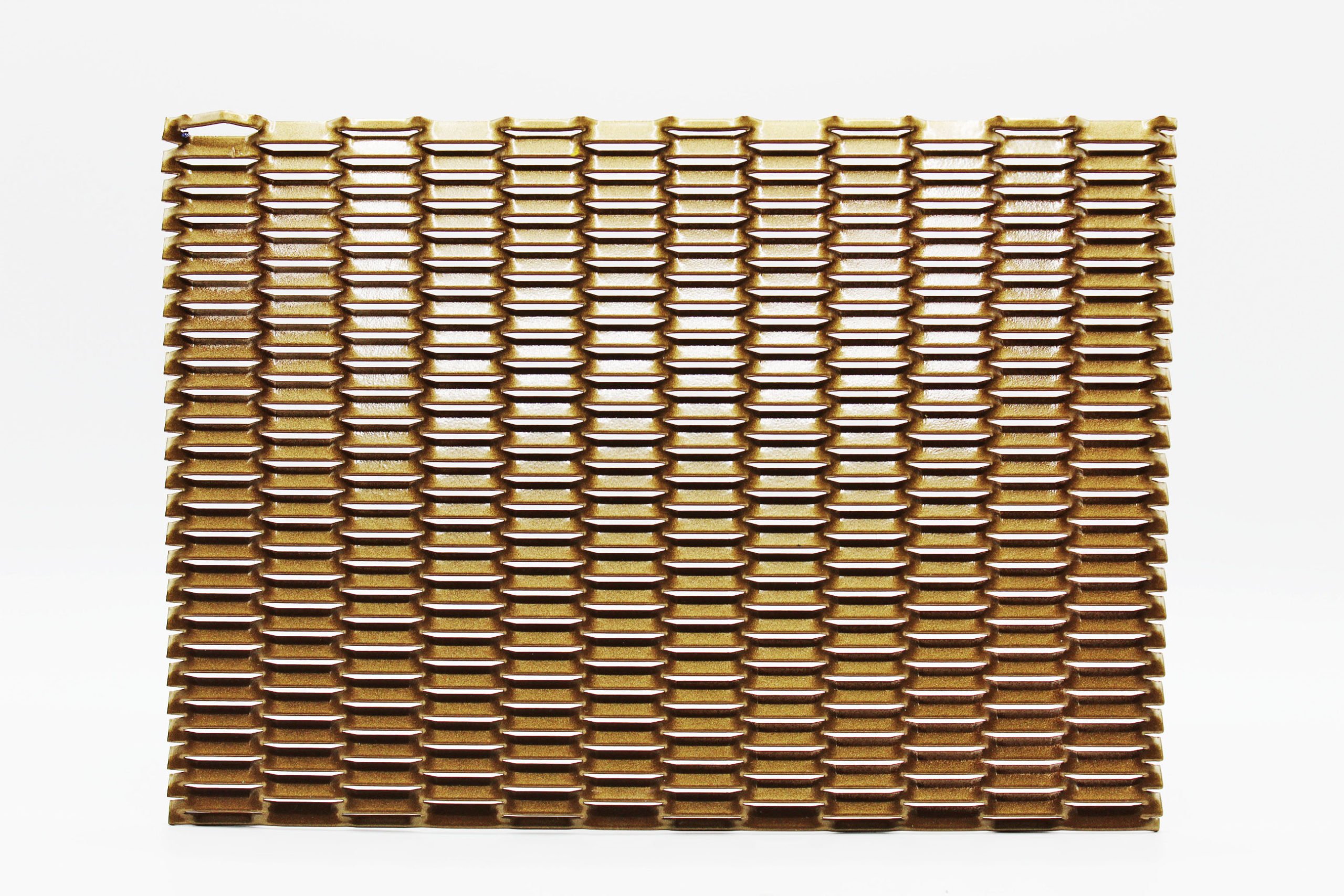

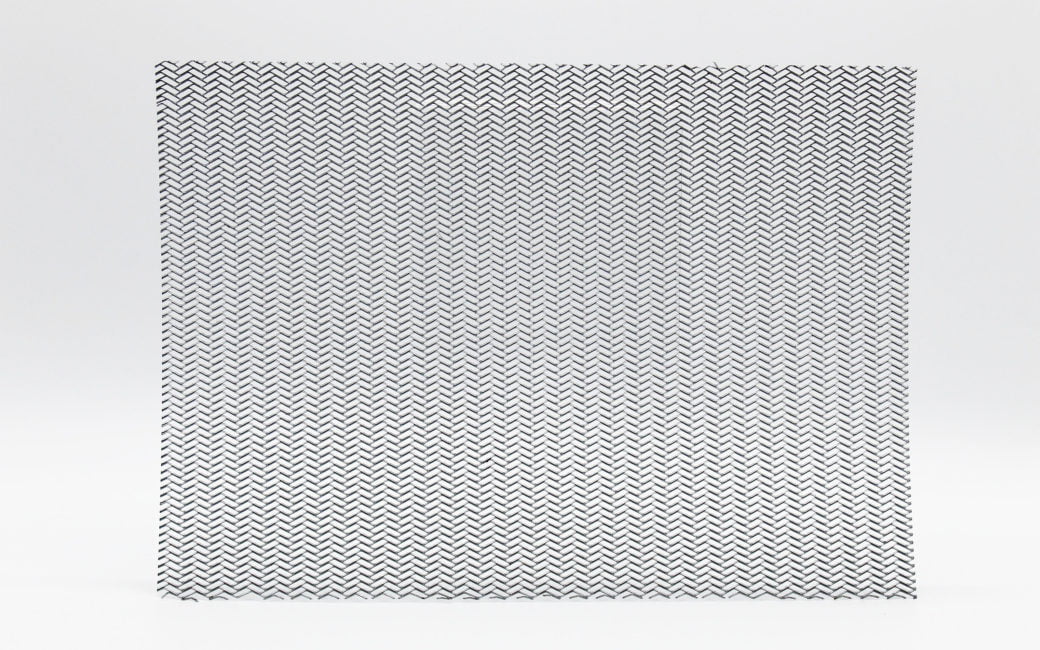

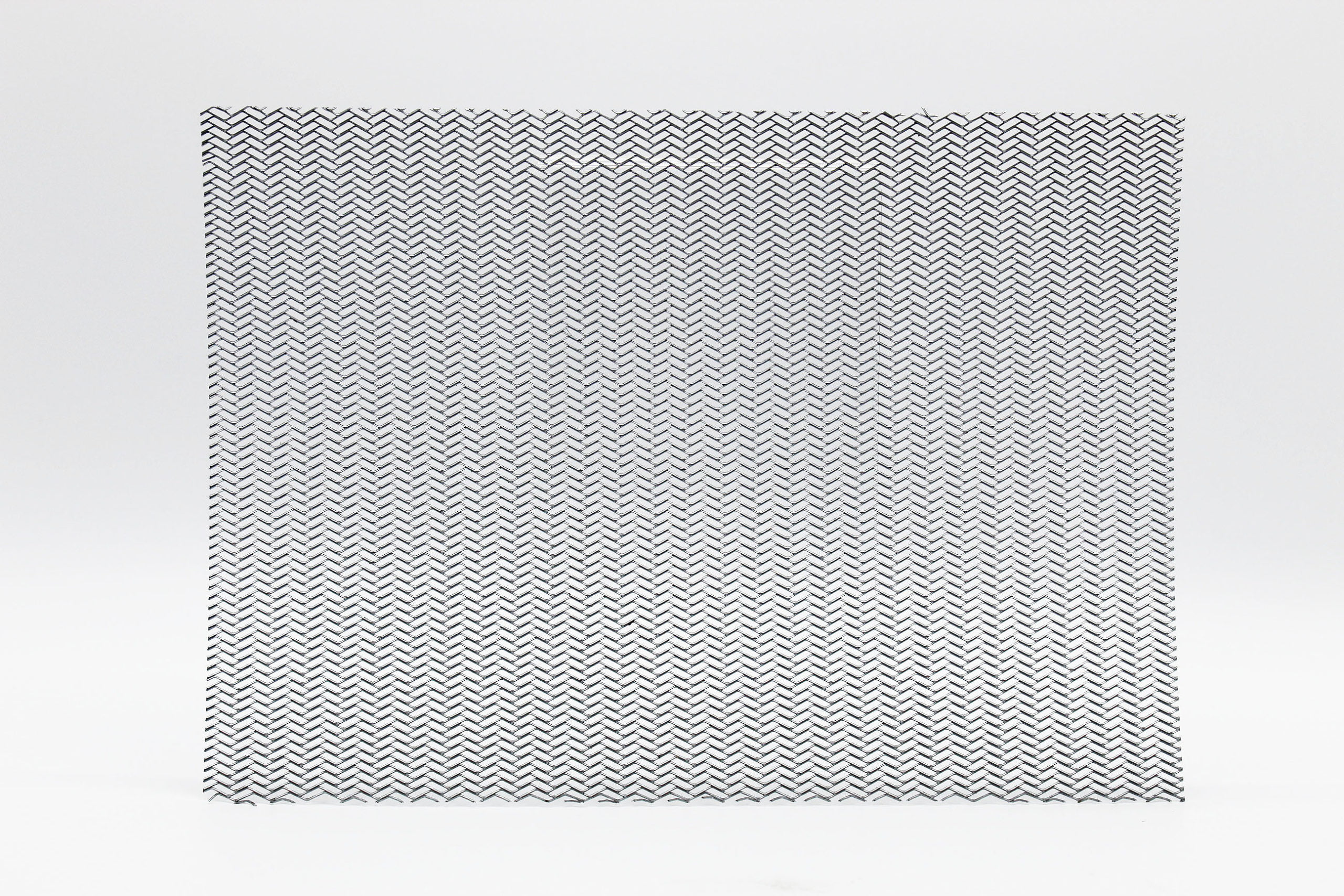

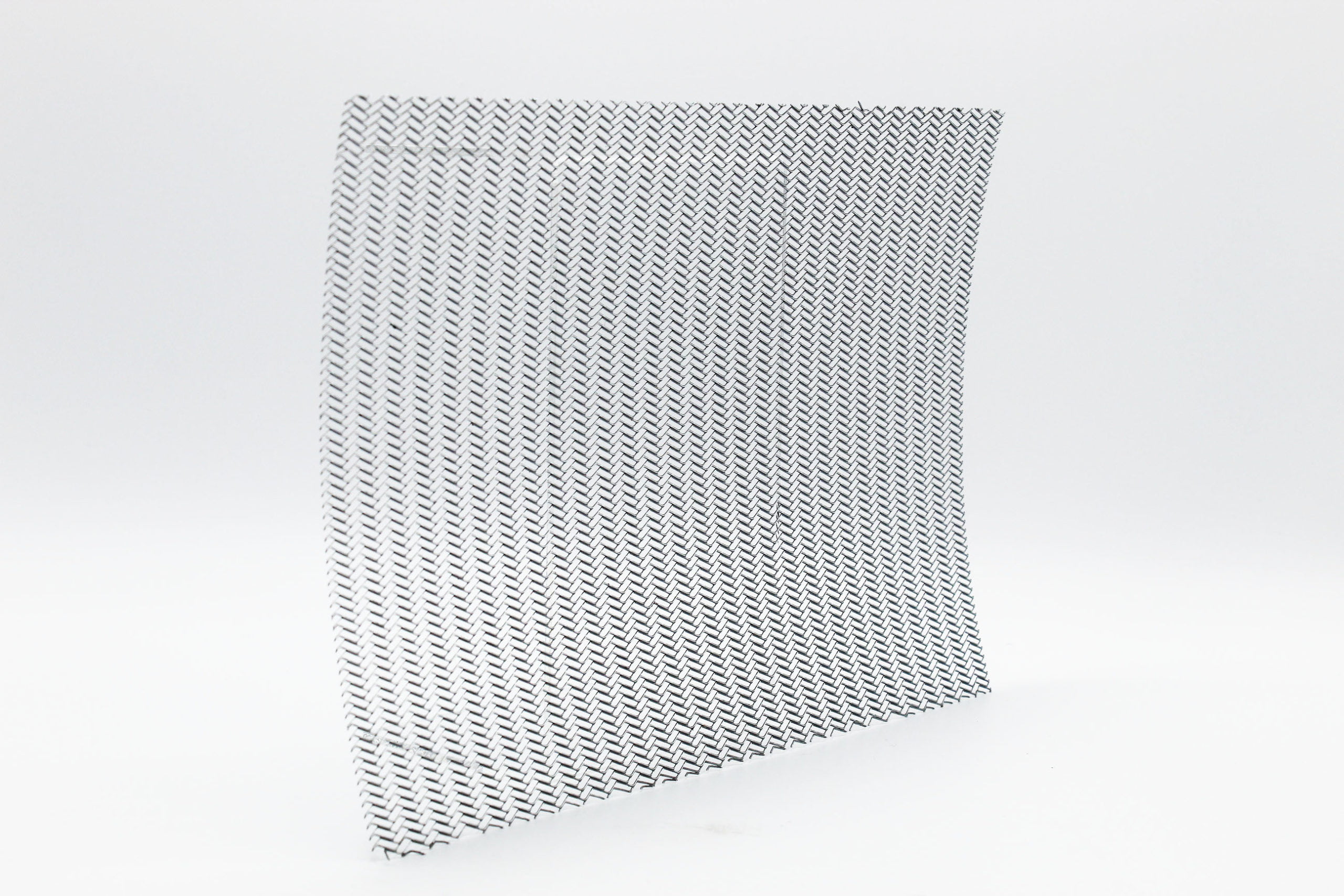

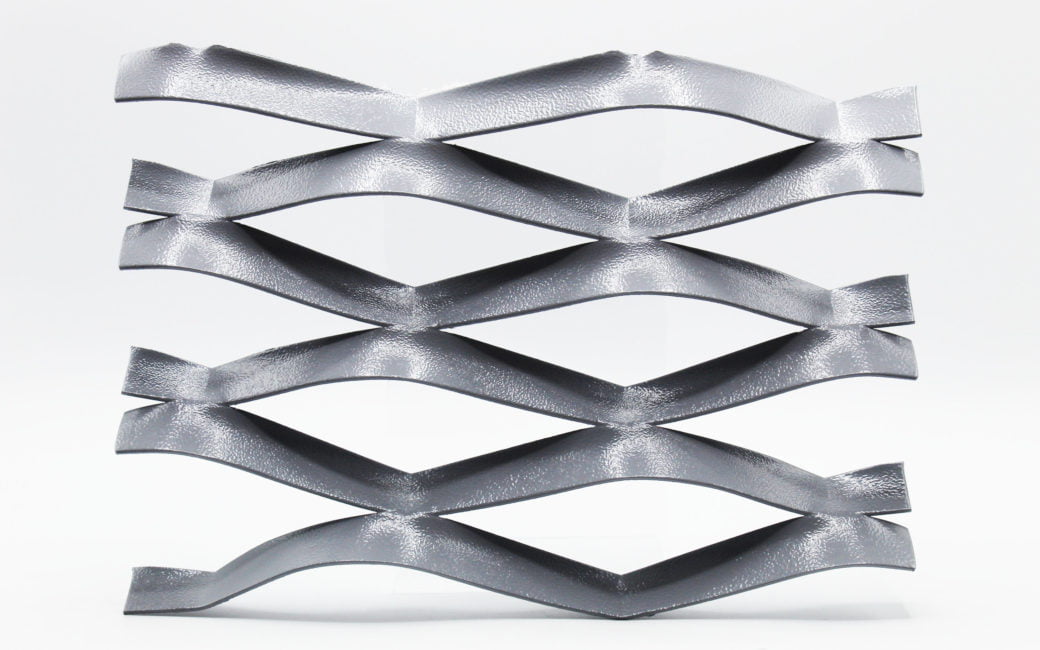

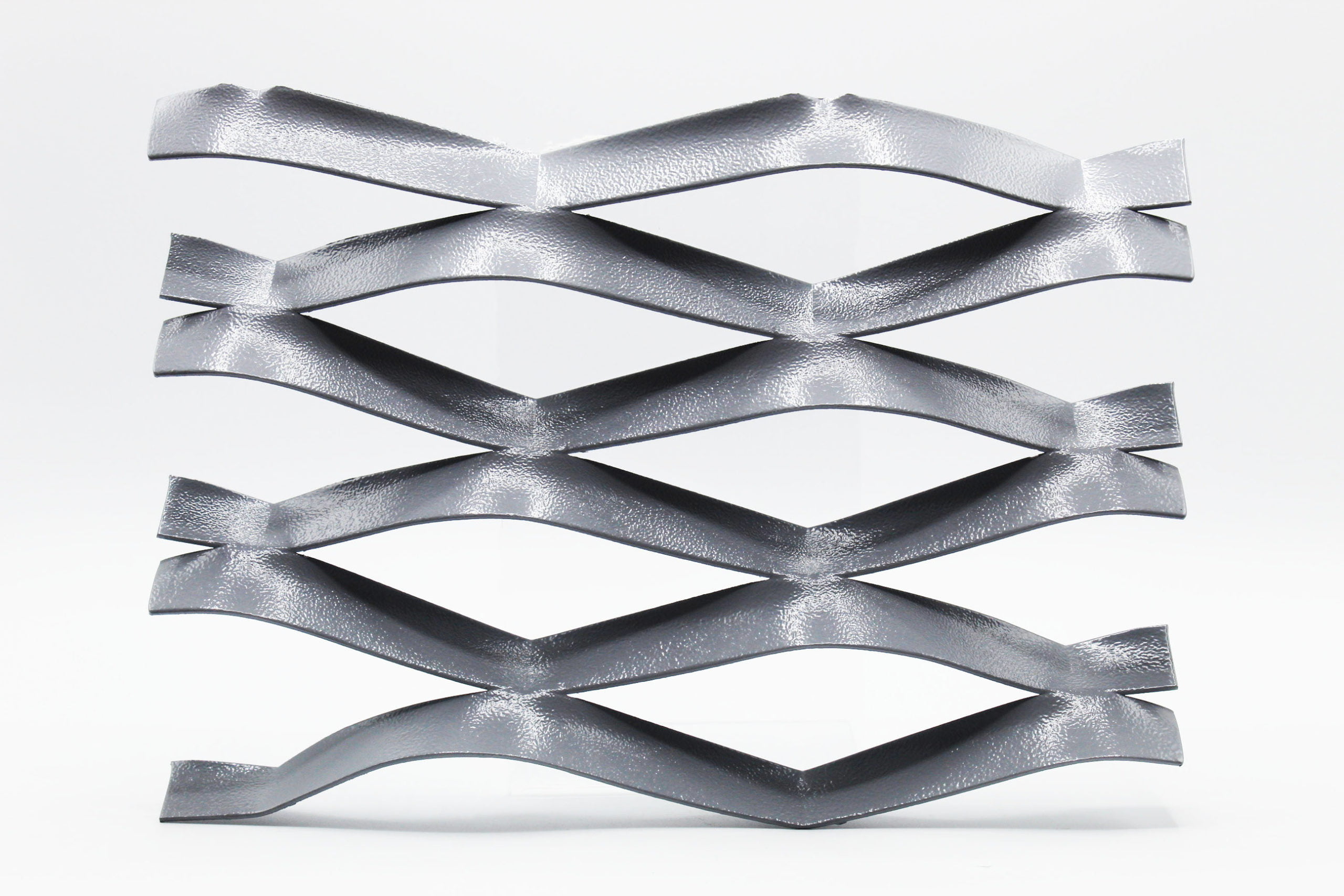

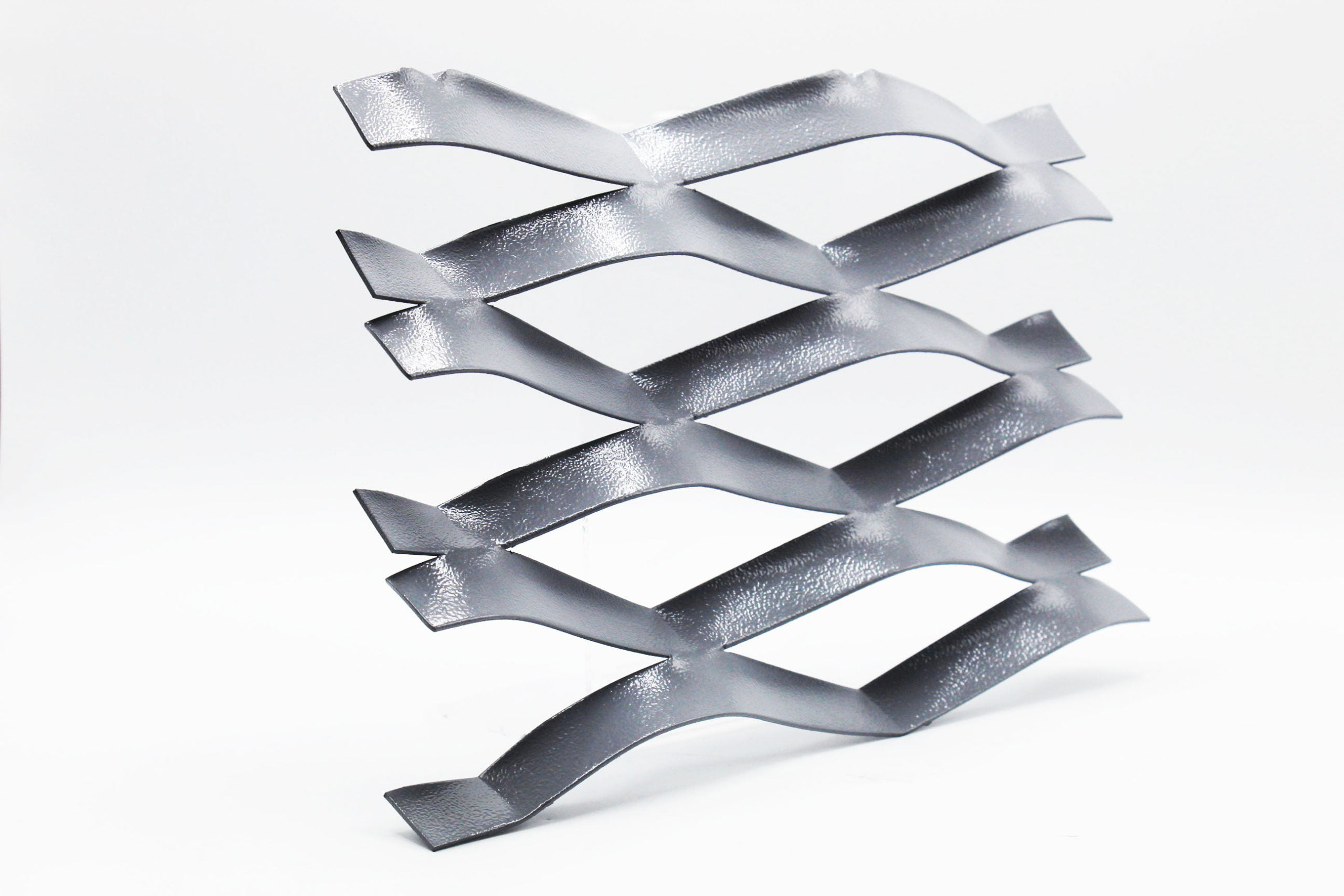

Aluminium Brocklebank 20/5 mesh at 2 Cumberland Place Dublin.

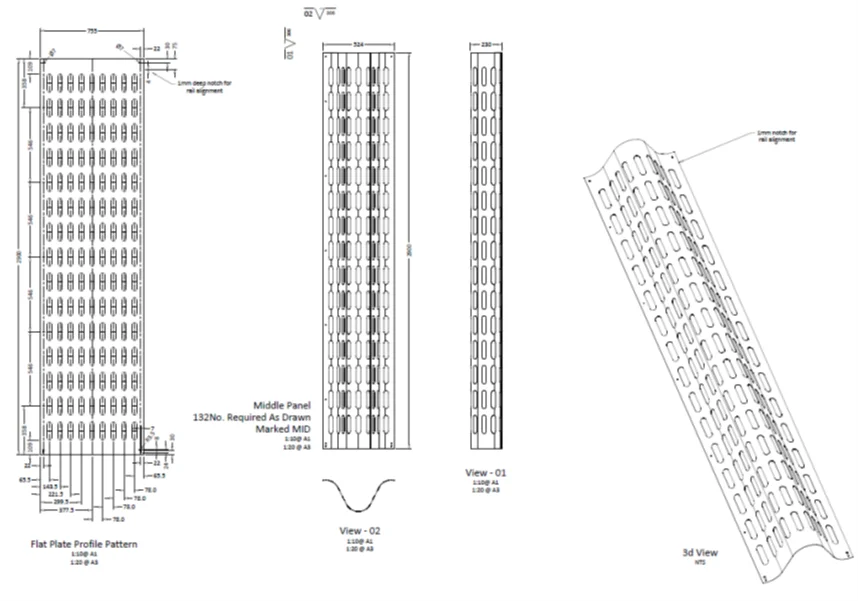

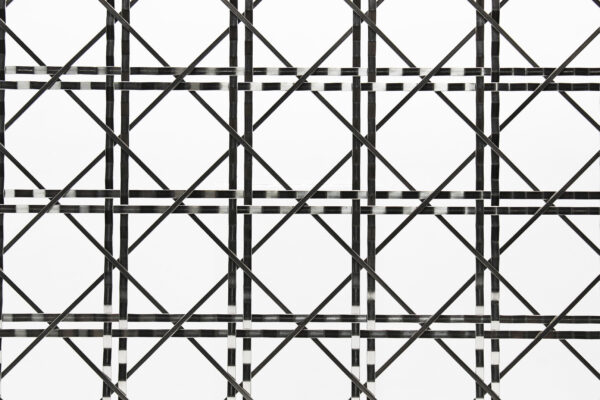

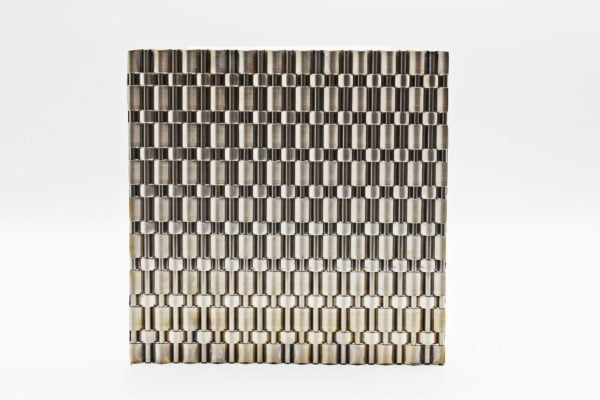

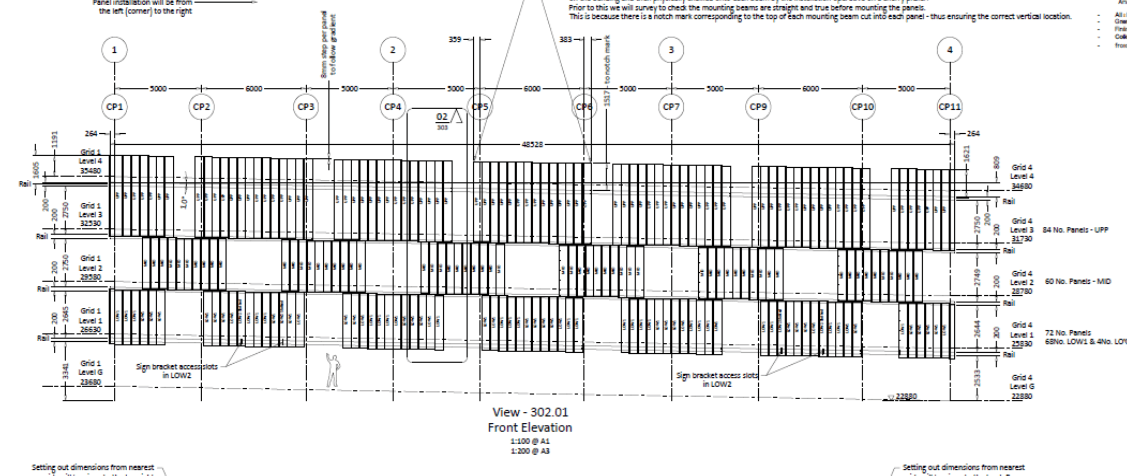

Over 500 panels of Brocklebank 20/5 were used to create the bronze fins which add texture to this modern glass façade.

The mesh was sandwiched in a box section frame, before being powder coated.

The mesh was installed by GLF Façade Specialists and specified by Billings Design Associates.

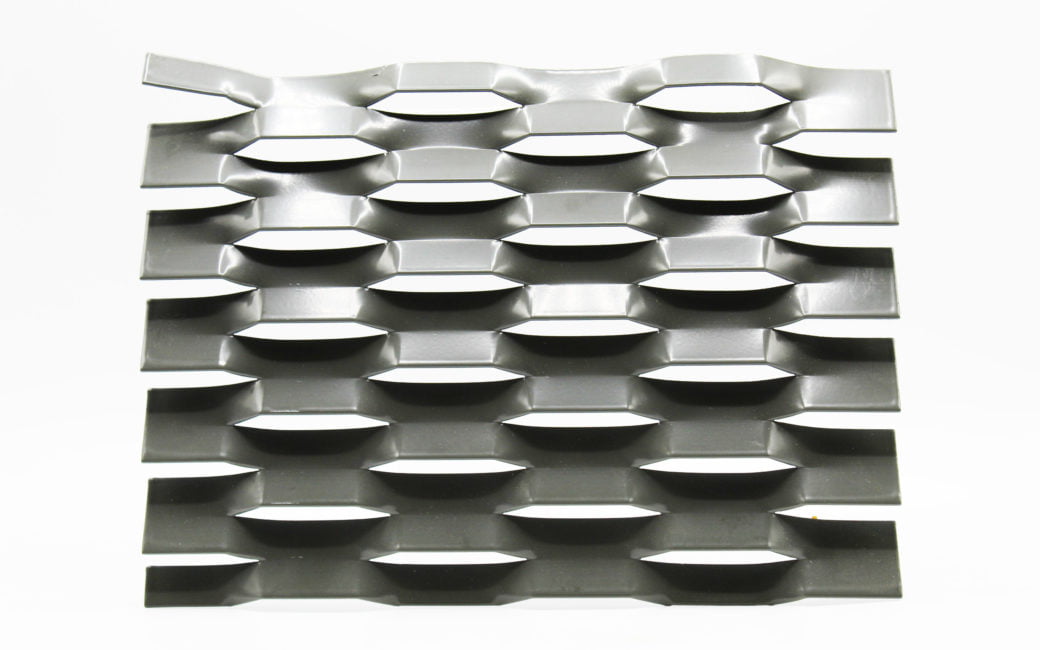

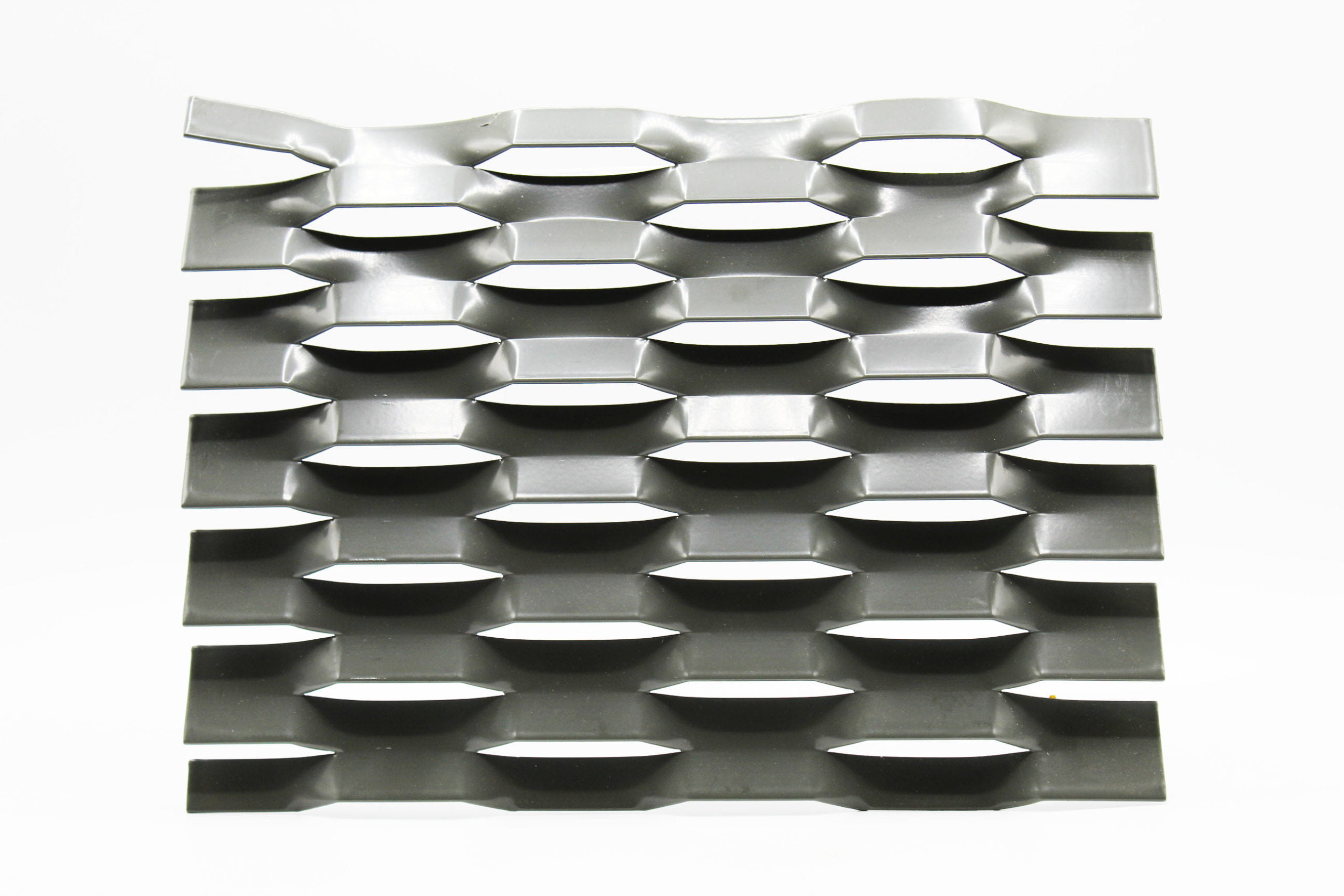

In tandem with the perforated metal supplied by others, the mesh forms a brise soleil for the office workers within the building.

Pictures courtesy of GLF Façade Specialists.