Non-Combustible Metal Mesh Cladding - Enhancing Safety and Sustainability

In recent years, the world has witnessed devastating incidents linked to combustible cladding materials in buildings. From residential complexes to commercial skyscrapers, the use of flammable materials in construction has posed significant risks to both life and property. In the wake of such tragedies, there's a pressing need to advocate for safer alternatives, and non-combustible metal mesh cladding emerges as a popular choice in this regard.

The Safety Imperative

First and foremost, the paramount concern in any construction project should be safety. Non-combustible cladding offers a crucial advantage in mitigating fire hazards compared to traditional combustible materials. By its very nature, metal mesh cladding significantly reduces the risk of fire propagation, enhancing the overall safety of the structure and its occupants.

Durability and Longevity

Beyond safety, metal mesh cladding boasts exceptional durability and longevity. Unlike combustible alternatives that may degrade over time, metal meshes maintain their structural integrity, providing lasting protection against external elements. This longevity not only ensures a safer environment but also translates into cost savings over the lifespan of the building.

Environmental Responsibility

In an era increasingly focused on sustainability, the environmental impact of construction materials cannot be overstated. Non-combustible cladding aligns seamlessly with sustainability objectives, offering a greener alternative to traditional options. By choosing non-combustible materials, builders and developers demonstrate a commitment to reducing carbon emissions and minimising their ecological footprint.

Regulatory Compliance and Peace of Mind

With stricter building regulations coming into force worldwide, compliance has become a critical consideration for construction projects. Opting for non-combustible cladding ensures adherence to stringent safety standards, providing stakeholders with peace of mind regarding regulatory compliance. By proactively choosing non-combustible materials, builders can avoid potential legal pitfalls and reputational damage associated with non-compliance.

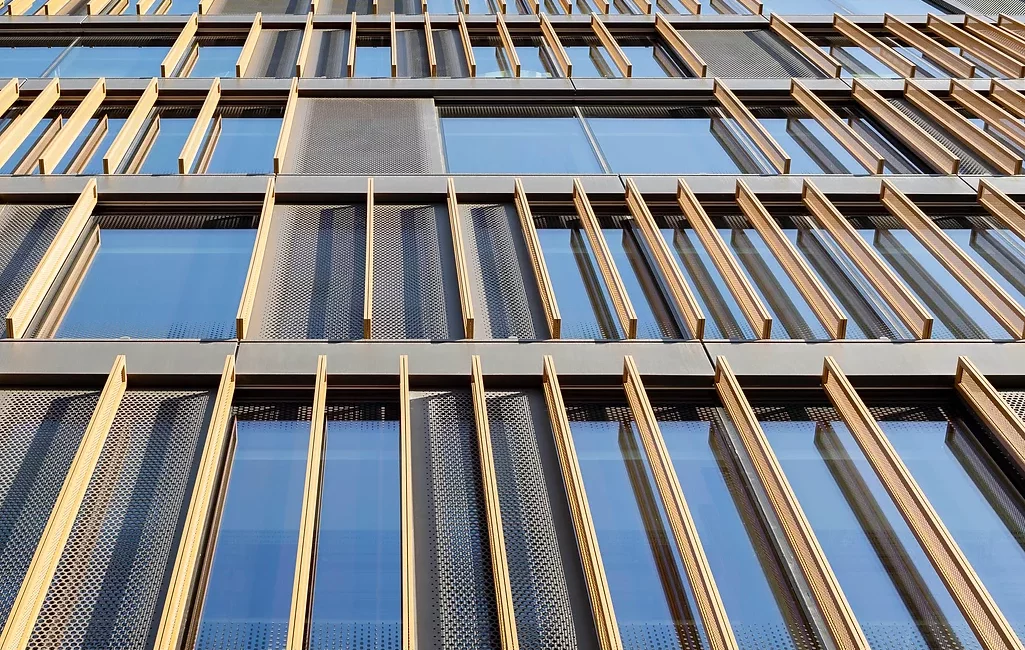

Architectural Versatility

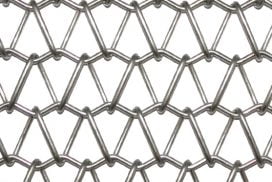

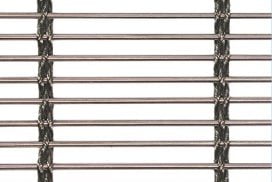

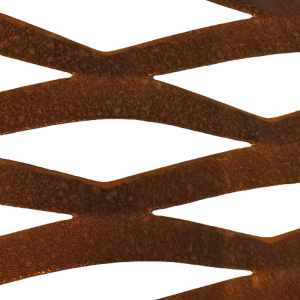

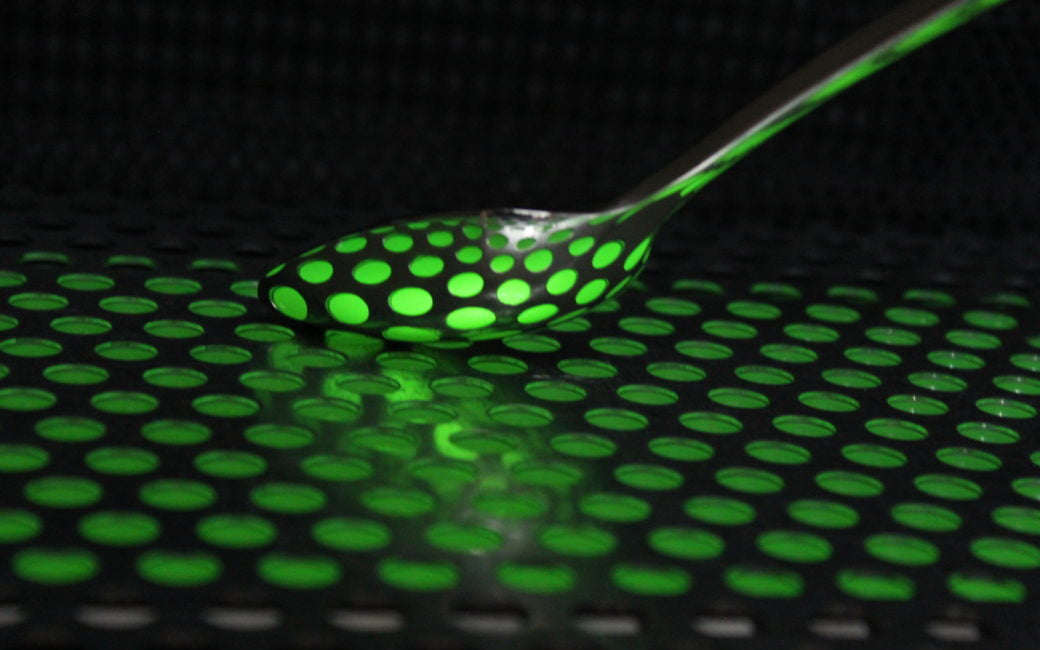

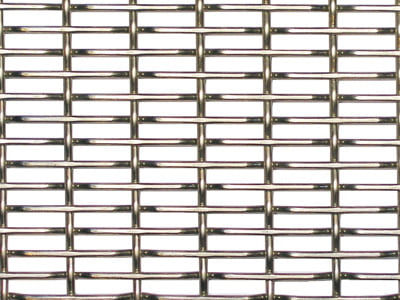

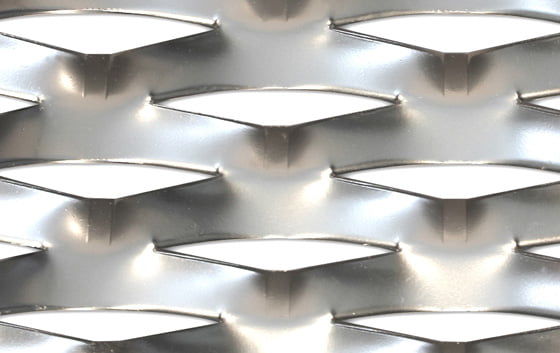

Contrary to common misconceptions, non-combustible cladding does not compromise on aesthetic appeal or design flexibility. Modern advancements in manufacturing techniques have resulted in a diverse range of metal mesh patterns, which offer architects and designers ample creative freedom. Whether pursuing sleek minimalism or intricate detailing, non-combustible metal cladding solutions can be tailored to suit any architectural vision.

Natural finishes, such as Corten Steel and Stainless Steel maintain resistance to combustion, whilst promoting sustainability, and enhancing aesthetic appeal.

Conclusion

In an industry where safety and sustainability are non-negotiable, the case for non-combustible cladding stands stronger than ever. By prioritising safety, durability, environmental responsibility, regulatory compliance, and architectural versatility, metal mesh materials offer a compelling proposition for construction projects of all scales.